How to set up an AC(Air Conditioner) Assembly Line factory?

Air Conditioner Assembly Lines/Production Lines are Suitable to Assemble/Produce Air Conditioners.(Welcome to contact us, we will suggest and design the suitable Assembly Lines/Production Lines for your Air conditioners.)

How to Establish an Air Conditioning Assembly Line Factory

Establishing an air conditioning assembly line factory requires systematic planning and significant resource investment. Below is a comprehensive step-by-step guide for starting from scratch:

Phase One: Strategic Planning and Preliminary Preparation

- Market Research and Business Plan

- Market Analysis: Identify the target market (residential, commercial, central air conditioning), product positioning (high-end, mid-range, economy), competitor analysis, market size, and growth forecasts.

- Product Definition: Decide on the types of air conditioners to produce (window units, split wall-mounted, split floor-standing, multi-split systems, chillers, etc.) and the cooling capacity range.

- Business Model: Choose between Own Brand Manufacturing (OBM), Original Design Manufacturing (ODM), or Original Equipment Manufacturing (OEM).

- Feasibility Study: Conduct a detailed assessment of Return on Investment (ROI), break-even point, and capital requirements.

- Develop a Complete Business Plan: Used to attract investment, apply for loans, and guide subsequent work.

- Technical and Process Planning

- Define Production Processes:

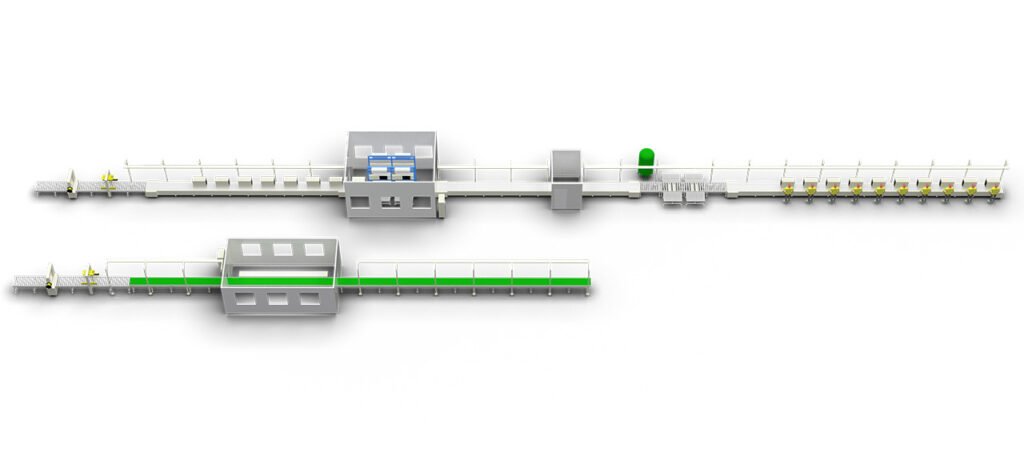

- Sheet metal processing (casing, chassis) → Heat exchanger (evaporator, condenser) production → Main assembly line (chassis installation, compressor installation, heat exchanger installation, electrical control box installation, pipe welding) → Helium leak testing / Vacuum drying → Refrigerant charging → Performance testing (online test chamber) → Finished product packaging.

- Establish Technical Standards and Specifications: Develop corporate product standards, process standards, and quality inspection standards based on national/international standards.

- Product Design and Development: Establish or commission an R&D team for product design, Bill of Materials (BOM) creation, and prototype testing.

- Define Production Processes:

- Site Selection and Factory Construction

- Site Selection Factors:

- Logistics: Proximity to major markets, supplier clusters, or transportation hubs.

- Infrastructure: Stable power supply (high load capacity), water supply and drainage, natural gas.

- Labor: Adequate supply of industrial workers and technical personnel.

- Policy: Local government industrial policies, tax incentives, land prices.

- Environmental Requirements: The factory must comply with environmental regulations, especially concerning waste gas and wastewater treatment.

- Factory Design and Construction:

- Plan total area (production workshop, warehouse, raw material area, finished goods area, testing area, office area, living quarters).

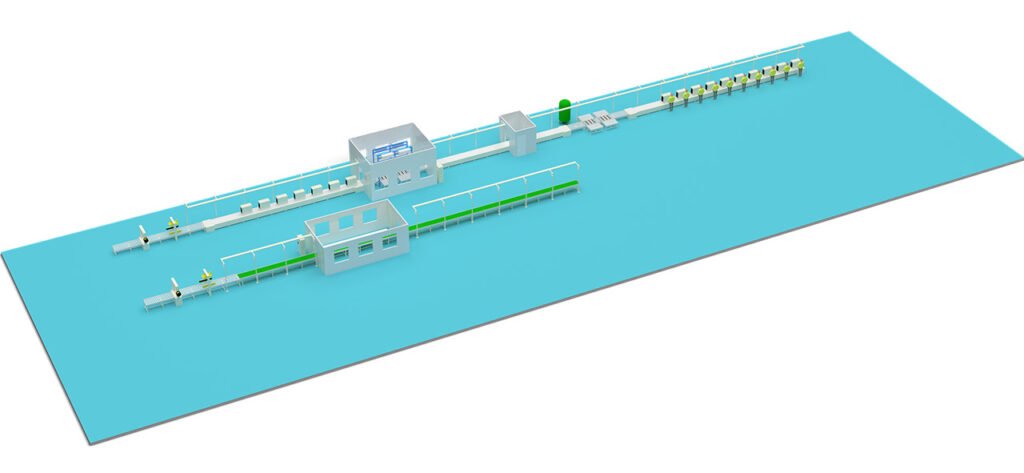

- Production line layout design (U-shaped or linear) to optimize material flow.

- Special workshop requirements: some areas need clean environments (e.g., electrical control board installation), good ventilation, floor load-bearing capacity, and crane access.

- Site Selection Factors:

Phase Two: Resource Preparation and Construction

- Supply Chain System Establishment

- Core Supplier Development and Qualification: Compressors, motors, copper tubes/aluminum fins for heat exchangers, electronic controllers (PCBA), valves (four-way valves, expansion valves), refrigerants, etc. Establish strict supplier audit and quality management systems.

- Develop Logistics and Inventory Strategies: Establish raw material warehouses, work-in-progress buffer zones, and finished goods warehouses. Plan for JIT (Just-In-Time) or safety stock models.

- Equipment Procurement and Installation

- Core Production Equipment:

- Sheet Metal Line: Uncoiler, punch press, bending machine, spot welder, painting line.

- Heat Exchanger Line: High-speed punch press (fins), tube bender, long U-bend machine, tube expander, welding equipment (flame welding or nitrogen-protected brazing).

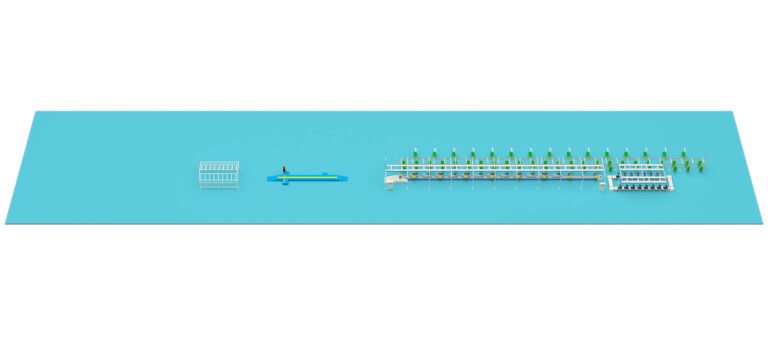

- Final Assembly Line: Conveyor lines (roller, chain-on-edge, belt), lifts, screwdriving machines (electric screwdrivers, torque wrenches), automatic dispensing machines, vacuum pumps, refrigerant charging machines, helium mass spectrometers for leak detection.

- Testing Equipment: Online performance test chambers (simulating operating conditions), noise test chambers, electrical safety testers, run-test stations.

- Others: Vacuum drying ovens, packaging machines, palletizers.

- Equipment Selection Principles: Choose based on capacity planning (e.g., annual output of 500,000 units), automation level (labor-intensive vs. automated), and investment budget. Options include new purchases, used equipment, or partial customization.

- Core Production Equipment:

- Team Building and Training

- Core Team: Recruit experienced General Manager, Production Plant Manager, Process Engineers, Quality Manager, Supply Chain Manager, Equipment Maintenance Engineers.

- Employee Recruitment and Training: Hire production line supervisors, operators, quality inspectors, warehouse keepers. Establish a systematic training system covering safety, processes, quality, and equipment operation.

Phase Three: Production Launch and Operation

- Installation, Debugging, and Trial Production

- Equipment delivery, installation, commissioning, and linkage.

- Conduct single-machine trial runs and full-line no-load and load debugging.

- Trial Production (Pilot Run): Use small batches of materials for production to verify the reliability of equipment, processes, and tooling/fixtures, and produce the first batch of samples.

- Mass Production Ramp-up and Continuous Improvement

- Start with low-speed production, gradually increasing cycle time and output, solving various issues that arise initially.

- Establish comprehensive production management systems (MES), quality management systems (SPC, FMEA), and a culture of continuous improvement (e.g., Lean Manufacturing).

Key Success Factors and Considerations:

- Capital: This is a capital-intensive industry with not small initial investment. Ensure healthy cash flow.

- Technology: Core technologies (e.g., system matching, control logic) and process know-how are critical. Consider partnering with established technical providers or recruiting talent.

- Quality: Air conditioners are durable consumer goods. Quality directly determines brand survival. Strict quality control must be implemented from design and the supply chain.

- Supply Chain Management: Air conditioners have numerous components. The stability, cost, and quality of the supply chain are paramount.

- Automation and Smart Manufacturing: Against the backdrop of rising labor costs, gradually introducing automation and robotics in welding, handling, inspection, and other links is a trend for improving efficiency and quality.

- Environmental Protection and Energy Efficiency: Strictly comply with environmental regulations. Increasingly stringent product energy efficiency standards are a key competitive advantage.

- Government Relations: Proactively communicate with local government to obtain potential support and ensure all approval procedures (environmental, fire safety, construction, etc.) are legally complete.

Recommendations:

For new entrants without industry experience, the safest approach is:

- Hire a consulting team with complete experience in building air conditioning factories.

- Collaborate deeply with core equipment suppliers (they often have extensive turnkey project experience).

- Consider starting with relatively simple assembly(SKD Assembly Line), outsourcing some core components (e.g., heat exchangers), and gradually extending upstream in the industry chain.