What is an SKD AC(Air Conditioner) Assembly Line?—SKD Air Conditioner Production Line

Air Conditioner Assembly Lines/Production Lines are Suitable to Assemble/Produce Air Conditioners.(Welcome to contact us, we will suggest and design the suitable Assembly Lines/Production Lines for your Air conditioners.)

The SKD Air Conditioning Assembly Line is an important stage or a specific model for establishing a complete assembly factory.

SKD, which stands for Semi-Knocked Down, refers to assembling major air conditioning components in near-complete module forms. It is an entry-level assembly model with relatively small investment and fast results.

I. Main Process Flow of an SKD Assembly Line

A typical SKD air conditioning assembly line mainly includes the following stations:

- Loading and Chassis Installation: Prefabricated chassis and casing are loaded onto the line.

- Core Module Installation:

- Install the pre-assembled compressor (usually with base and vibration pads).

- Install the pre-assembled indoor unit evaporator assembly and outdoor unit condenser assembly (with fins already installed and pipe connections welded).

- Install the electrical control box assembly (with PCBA already installed in the box).

- Tubing Connection and Welding: Position the connecting copper pipes between modules and perform brazing (flame welding or nitrogen-protected brazing). This is a key technical and quality control point on the SKD line.

- Leak Detection: Perform leak detection on the welded system (commonly using helium mass spectrometry or underwater bubble testing).

- Vacuuming and Drying: Use a vacuum pump to evacuate the system piping to a high vacuum to remove moisture and air.

- Refrigerant Charging: Charge a quantitative of refrigerant (e.g., R32, R410A) according to the model.

- Performance Testing: Power on and run the unit in an online test chamber, simulating cooling/heating conditions to test key parameters (current, pressure, outlet air temperature, noise, etc.).

- Final Assembly and Packaging: Install fans, fan blades, panels, apply labels, and proceed to packing and palletizing.

II. Key Steps to Establish an SKD Assembly Line (Simplified)

- Define Module Sourcing Strategy: Negotiate with upstream suppliers (could be the parent company or third-party module factories) to determine which modules to purchase (e.g., heat exchanger assemblies, compressor modules, electrical control assemblies) and which simple parts to source locally (e.g., screws, packaging materials).

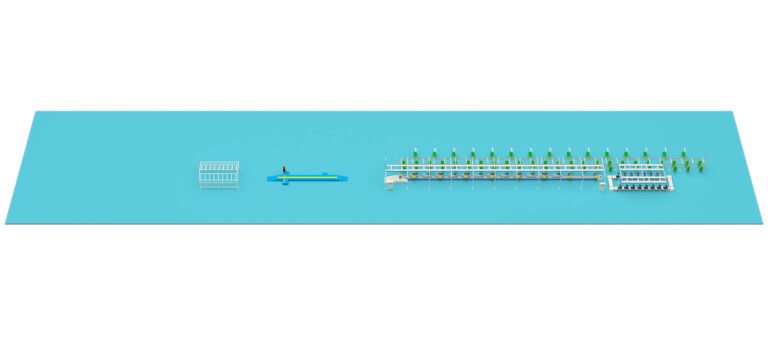

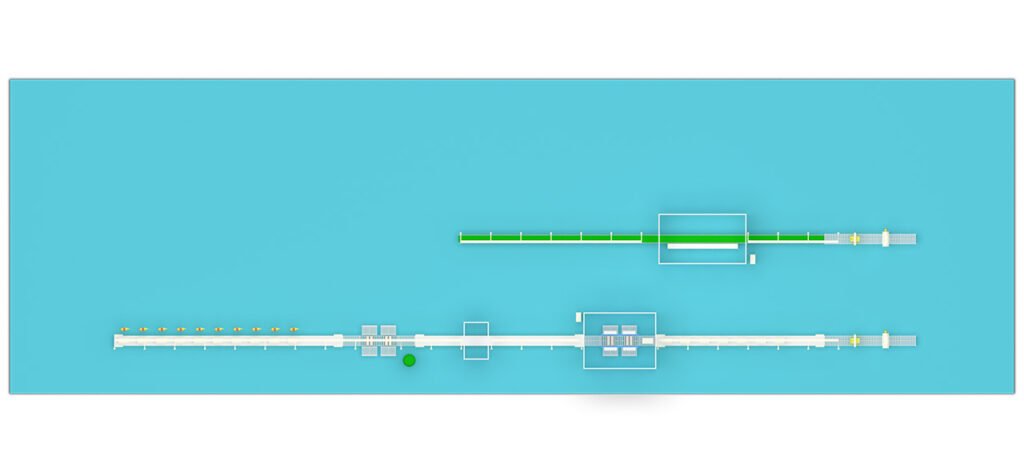

- Design Production Line Layout: Design one or several U-shaped or linear assembly lines based on production cycle time (e.g., hourly/daily output), and plan material feeding routes.

- Core Equipment Procurement:

- Conveyor Lines: Chain-on-edge or roller conveyors.

- Welding Equipment: Torches, pressure regulators, nitrogen cylinders, and piping.

- Vacuum and Charging Equipment: Vacuum pumps, electronic scales, refrigerant charging machines.

- Leak Detection Equipment: Helium leak detectors or bubble test tanks.

- Testing Equipment: Online performance test chambers (the core and most expensive testing equipment), electrical safety testers.

- Tools: Torque-controlled electric screwdrivers, tube cutters, flaring tools.

- Establish Quality System: Focus on Incoming Quality Control (for purchased modules), In-Process Inspection (welding quality, cleanliness), and Final Testing (performance pass rate). Welders must be certified.

- Personnel Training: Training focuses on safety regulations (especially for refrigerant and welding), standard operating procedures, and quality judgment.

III. Advantages and Risks

- Advantages:

- Rapid startup, enabling quick response to market demand.

- Reduces investment risk and technical barriers.

- Easier to manage, focusing on final assembly and testing.

- Benefits from tariff, logistics, and other cost advantages of localized production.

- Risks and Challenges:

- High dependency on the supply chain, as module supply and pricing are controlled by others.

- Thin profit margins due to fewer value-added steps.

- Quality control heavily relies on suppliers; incoming material issues can halt the entire line.

- Limited technological advancement, making it difficult to accumulate deep expertise in core component manufacturing and system matching.

Summary and Recommendations

For many companies, SKD is a very pragmatic and efficient choice for entering the air conditioning manufacturing sector. It is often used as:

- The first step for testing the market.

- A transitional phase for shifting from trading to manufacturing.

- A strategy to achieve a “locally produced” label in the target sales region to meet policy or customer requirements.

The keys to success are: selecting reliable and collaborative module suppliers, establishing strict and efficient incoming inspection and assembly/testing processes, and cultivating a skilled and stable team of on-site technical workers.

Once the SKD model operates maturely, the company can gradually extend upstream, transitioning some modules (e.g., heat exchangers) to in-house production, moving towards a CKD model to increase profits and competitiveness.