Wheeled Tractor Assembly Line—What is a Wheeled Tractor Assembly Line?

I. Core Features & Design Focus

- “Axle-Wheel” Assembly as the Backbone

- The main assembly line closely revolves around the positioning, mating, and adjustment of the front axle assembly and rear axle assembly. The positioning accuracy of the axles directly determines the vehicle’s alignment and driving performance.

- Wheel assembly (tire + rim) installation is one of the most labor-intensive workstations with the highest tooling requirements, involving heavy handling and high-torque fastening.

- “Wheel Alignment” is the Lifeline of Quality

- This is a unique and mandatory core inspection process for wheeled tractors. The precision of parameters like toe-in and camber directly affects straight-line stability, steering ease, and tire wear.

- The line must integrate high-precision laser or CCD wheel alignment systems. Their measurement data forms a critical part of the final vehicle’s quality record.

- High Focus on Drivetrain and Steering System Integration

- Drivetrain Matching: The connection of the propeller shafts between the engine, transmission, and front/rear drive axles demands extremely high coaxiality.

- Steering System Assembly: The installation and adjustment of the steering gear, pitman arm, and tie rods are fundamental to ensuring controllability.

- Brake System Assembly: The routing and leak testing of air or hydraulic brake lines are crucial.

- Coping with High Configuration Flexibility

- Wheeled tractors have a vast array of options: different track widths (adjustable rims), different tires (field, paddy, industrial), front/rear ballast weights, various hydraulic valve groups, different cabs, etc.

- The assembly line must possess the capability for rapid identification, parts calling, and assembly of different options.

II. Core Process Flow & Key Workstations

The main flow of a typical modern wheeled tractor assembly line is as follows:

Phase 1: Chassis Frame Construction

- Chassis Framing On-line: The painted chassis frame is placed onto the assembly pallet via hoist or other equipment.

- Front/Rear Axle Mating:

- The pre-assembled front and rear axle assemblies (with brakes, differential, final drive installed) are precisely positioned and fastened to the chassis frame. This station often uses high-precision locating pins and servo-controlled tightening systems.

Phase 2: Powertrain & Drivetrain Installation

- Powertrain Hoisting: The combined engine and transmission unit is hoisted and mounted onto the chassis mounts.

- Propeller Shaft Connection: Connecting the propeller shafts from the transmission output to the front and rear drive axles.

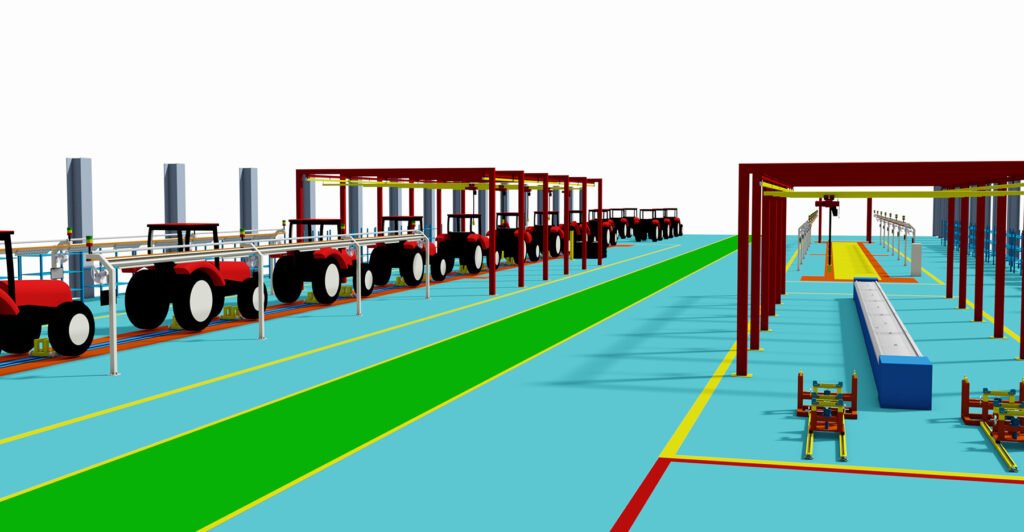

Phase 3: Running Gear Installation (Wheeled Characteristic)

- Tire Sub-assembly & Delivery:

- In a dedicated area, tires are mounted onto rims and undergo dynamic balancing (especially important for high-horsepower, high-speed models).

- Tire assemblies are delivered to the main line stations in sequence via AGVs or continuous conveyors.

- Wheel Mounting & Fastening:

- Balanced manipulators are used to handle the heavy tire assemblies onto the axle hubs.

- Multi-spindle torque tightening machines or high-precision electric tools are used to fasten the wheel nuts in a specific cross-sequence with defined torque values. All torque values must be 100% uploaded to the MES system for traceability.

Phase 4: Upper Structure Integration

- Hydraulic & Electrical System Installation: Installing the hydraulic tank, pump, multi-valve block, and routing the complex network of hydraulic hardlines and hoses; routing the main vehicle wiring harness.

- Cab Assembly Installation: Hoisting and securing the pre-assembled cab unit (with interior, dashboard) onto the chassis frame.

- Fluid Fill & Covers Installation: Filling engine oil, coolant, hydraulic fluid, fuel; installing the engine hood, fenders, etc.

Phase 5: End-of-Line Testing & Adjustment (Core Quality Gates)

- Preliminary Toe-in Adjustment: A rough toe-in adjustment is performed before the tractor leaves the main line.

- Wheel Alignment Check: The tractor drives onto an online alignment test bed for precise measurement and adjustment. This is a critical, non-bypassable quality gate.

- Comprehensive Performance Testing:

- Roller Brake Test: Testing service and parking brake performance.

- Hydraulic Test: Testing lift capacity, hydraulic outlet pressure and flow.

- Electrical Test: Verifying all lights, instruments, and controller functions.

- Dynamic Run-off: A short driving test on a roller dynamometer or test track to check gear shifts, steering, unusual noises, etc.

- Final Visual Inspection & Delivery.

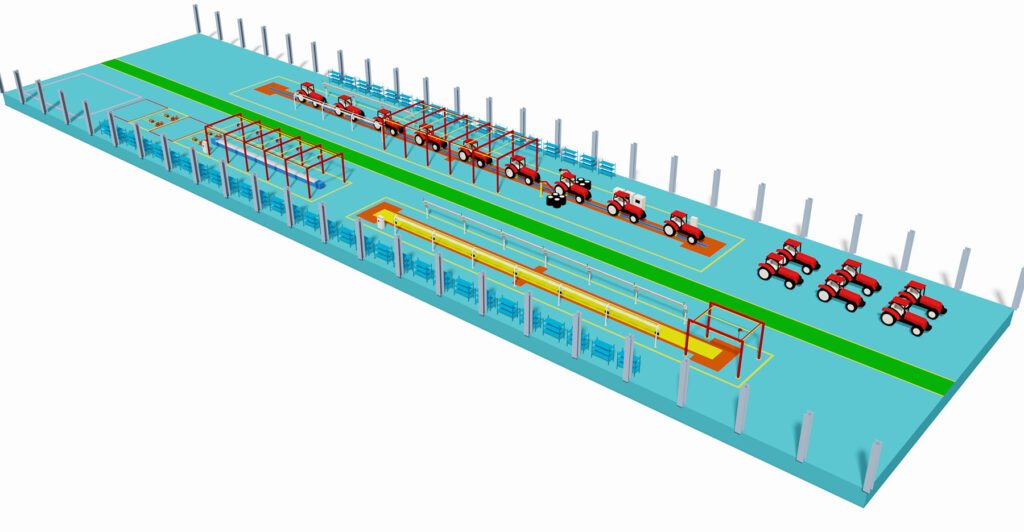

III. Layout & Logistics Keys

- “H” or “U” Shaped Layout: Common layouts where the main line is in the center, with sub-assembly lines for major units (engine, cab, axles) on the sides or at one end, feeding into the main line.

- Intelligent Tire Delivery: Due to the variety and weight of tires, automated storage/retrieval systems (AS/RS) for order-based picking are often used, which is key to flexible production.

- Full-process Assist & Data Traceability: Ergonomic assist devices are ubiquitous at heavy-handling stations (engine, tires, cab); full data traceability is implemented at critical fastening and inspection stations.

Conclusion: Core Investment & Selection Points for Wheeled Lines

When planning or selecting a wheeled tractor assembly line, technological investment should prioritize solving its inherent challenges:

- The Precision Challenge: Investment is needed in high-precision axle positioning/mating equipment and online wheel alignment systems to ensure driving performance.

- The Strength vs. Efficiency Challenge: Investment is needed in automated wheel fastening systems and tire handling assist devices to ensure quality, efficiency, and ergonomics.

- The Complexity vs. Flexibility Challenge: Reliance on a robust MES system and flexible logistics is required to manage the vast number of configuration options and enable mixed-model production.

An excellent wheeled tractor assembly line does not merely put parts together. It ensures, through precise process control, that every tractor rolling off the line possesses excellent straight-line stability and steering feel. This is where its true value lies.