What is a CKD AC(Air Conditioner) Assembly Line?—CKD Air Conditioner Production Line

Air Conditioner Assembly Lines/Production Lines are Suitable to Assemble/Produce Air Conditioners.(Welcome to contact us, we will suggest and design the suitable Assembly Lines/Production Lines for your Air conditioners.)

CKD, or Completely Knocked Down, refers to purchasing all the most basic individual components and completing the entire manufacturing process—from component processing to final unit assembly and testing—within a self-built factory. This signifies the establishment of full manufacturing capabilities and deep localization.

The following is a comprehensive analysis of the CKD air conditioning assembly line:

I. The Core Nature and Value of the CKD Model

CKD is not just assembly; it means possessing a complete air conditioning manufacturing plant. Its core value lies in:

- Mastering the Core Technology Chain: The enterprise controls almost all process stages from raw materials to finished products, especially the manufacturing of heat exchangers (evaporators, condensers) and complete system matching technology, which are the core of air conditioning.

- Maximizing Cost Control: Through large-scale procurement of raw materials (copper tubes, aluminum foil, steel sheets, etc.) and in-house production of core components, material costs can be significantly reduced, yielding much greater profit margins than SKD.

- Supply Chain Autonomy and Flexibility: Reduces dependence on a few module suppliers, allows flexible selection of component suppliers, and enhances the ability to cope with market fluctuations.

- Comprehensive Quality Control: Controls the quality of every component from the source and the process of every step, enabling systematic improvement and assurance of final product consistency and reliability.

- Meeting Higher Localization Rate Requirements: In many countries, the CKD model is the basis for meeting so-called “domestication” standards and enjoying higher policy incentives.

II. The Complete Process Flow of a CKD Assembly Line

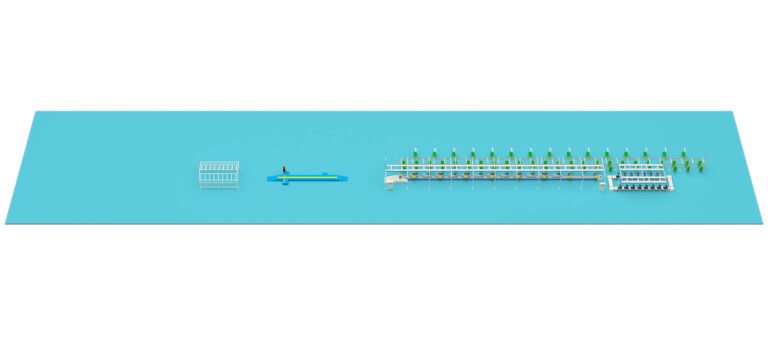

A complete CKD air conditioning production line is a combination of several specialized workshops, far more complex than SKD:

1. Sheet Metal Workshop

- Processes: Uncoiling coil steel → Stamping/forming → Bending → Welding (spot welding, CO₂ welding) → Pre-treatment (degreasing, phosphating) → Painting (powder coating or wet painting) → Curing.

- Output: All metal structural parts for indoor and outdoor units: casings, chassis, panels, frames, etc.

2. Heat Exchanger Workshop – The Technical Core of CKD

- Processes:

- Condenser/Evaporator Manufacturing: Copper tube cutting & bending → Inserting aluminum fins → Tube expanding (for tight contact) → U-bend/header welding → Leak testing.

- Component Preparation: Sub-assembly of parts like motors, fan blades, and electric auxiliary heaters.

- Output: Manufacturing the most critical heat exchange components of the air conditioner.

3. Final Assembly Line – Integration and Testing

- This is where outputs from the first two workshops meet purchased core components (compressors, controllers, valves, etc.).

- The main line flow is similar to SKD but starts differently: beginning with installing self-produced chassis and casings.

- Chassis loading → Compressor installation → Installation of self-produced heat exchangers → Electrical control box installation → Pipe welding → Leak detection → Vacuum drying → Refrigerant charging → Performance testing → Fan and panel installation → Packaging.

- Key Difference: Vastly increased welding workload, and system matching (refrigerant charge amount, expansion device selection, etc.) requires independent calculation and debugging.

4. Injection Molding Workshop (Optional)

- If plastic parts (e.g., grilles, louvers, bases) are also produced in-house, injection molding machines and molds are needed.

III. Critical Elements and Investment for Establishing a CKD Line

- Comprehensive Technical Capabilities

- Product R&D and System Matching Capability: This is the soul. Requires an R&D team for thermal calculations, structural design, control logic development, noise optimization, etc.

- Complex Process Engineering Capability: Requires expertise in various industrial technologies like stamping, welding, painting, tube expanding, brazing, and vacuum processing.

- Complete Quality Inspection System: Requires establishing laboratories (e.g., material lab, noise lab, endurance run lab) for inspections ranging from incoming raw materials to in-process IPQC and final product testing.

- Substantial Equipment Investment

- Sheet Metal Line: Large punch presses, CNC bending machines, automated welding robots, pre-treatment lines, automated painting lines, and curing ovens.

- Heat Exchanger Line: High-speed punch presses (for fins), long U-bend machines, tube expanders, automatic fin stacking machines, heat exchanger welding lines.

- Final Assembly Line: Highly automated conveyors, robotic assistance for assembly, automated welding stations, fully automatic refrigerant charging machines, high-precision test chambers.

- Utilities: Large investment in air compressors, cooling towers, pure water systems, and environmental treatment facilities (for waste gas and water).

- Extremely Complex Supply Chain Management

- Requires managing hundreds of suppliers covering almost all industrial sectors: metal materials, chemical coatings, compressors, motors, chips, capacitors, valves, packaging, etc.

- Requires establishing a strong team for supply chain management, procurement, and logistics.

- Large-scale Human Resources

- Requires a team of engineers and technicians spanning R&D, process, quality, production, equipment, supply chain, and other fields.

- Requires training a large number of skilled workers, such as welders, painters, and equipment operators.

Summary

Establishing a CKD Air Conditioning Assembly Line Factory is an signature of a country or region establishing a complete air conditioning industry system. It is an extremely complex systems engineering project, an ultimate test of capital, technology, talent, and management.