Tricycle Assembly Lines/Production Lines are Suitable to Produce/Assemble 3 wheeler, tricycles, and so on.(If customers request, we also can design the Production Line/Assembly Line suitable for 2 wheeler and 3 wheeler depends on exact vehicle models.)

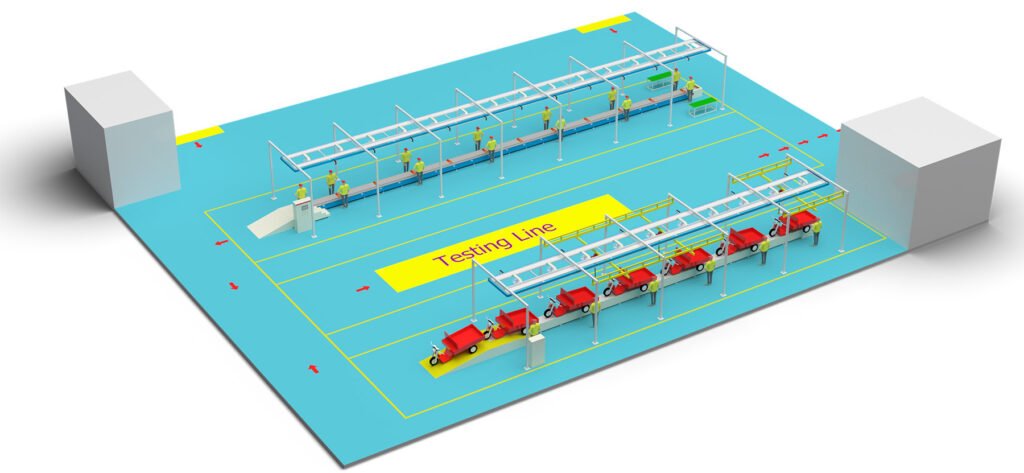

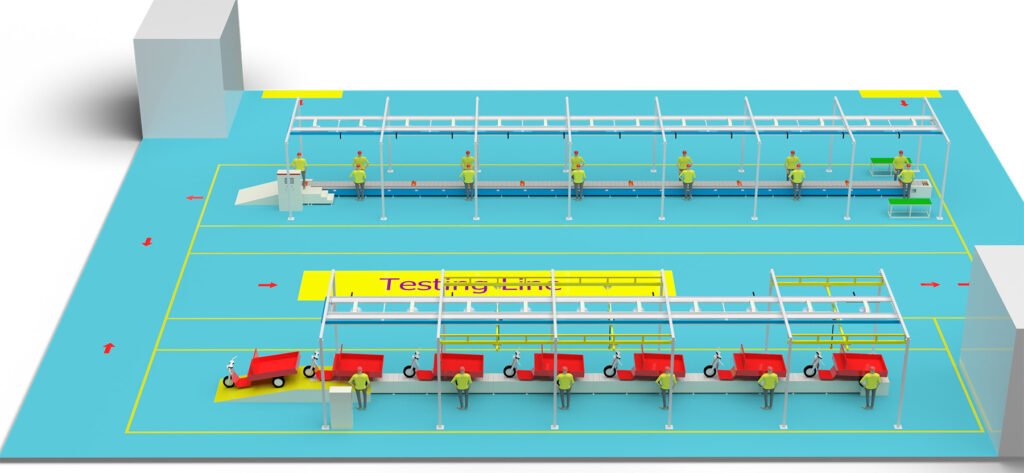

Three-Wheeler Assembly Line – Complete Solutions

We provide efficient, reliable, and modern three-wheeler assembly lines, designed to meet diverse production needs for various capacities and models (for cargo, passenger, and special applications). Our assembly lines are dedicated to helping customers improve product quality, reduce production costs, optimize production cycle times, and achieve a perfect combination of scale and flexibility.

1. Main Components of the Assembly Line

A complete three-wheeler assembly line typically consists of the following core systems:

- Conveyor System

- Types: slat conveyors on the ground or under the ground.

- Function: Transports the chassis and the vehicle-in-progress smoothly and continuously through each station, ensuring a stable production pace.

- Process Assembly System

- Chassis Loading & Pre-assembly Station: Chassis hoisting, positioning, and initial installation of components like the front fork and pedals.

- Powertrain Installation Station: Hoisting and securing of the engine/motor, transmission, and rear axle assemblies.

- Wheel Installation Station: Automated or semi-automated tire mounting, inflation, wheel balancing, and installation onto the vehicle.

- Wiring Harness & Control System Station: Routing the full vehicle wiring harness, installing the battery, controller, instrument panel, etc.

- Body Panels Installation Station: Installing the cab, cargo box, fenders, seats, etc.

- Fluids Filling Station: Centralized filling of fuel, lubricants, coolant, brake fluid, etc.

- Final Inspection & Testing Station: Includes safety performance checks for lighting, brakes, steering, speed, etc.

- Tools & Equipment System

- Specialized Tools: Electric/pneumatic torque wrenches, tire changers, fluid fillers, etc.

- Balancing Hoists: For the precise positioning and hoisting of heavy components like engines and cabs.

- Quality Inspection & Control System

- Online Inspection: Quality checkpoints at each critical station for real-time monitoring.

- Final Inspection Line: Includes headlight tester, side slip tester, brake tester, chassis inspection pit, etc.

- Data Traceability: Records assembly data and quality information for key components via an MES, enabling full traceability.

- Information Management System

- Manufacturing Execution System: Monitors production progress, material consumption, equipment status, and product quality.

- Andon System: Allows operators to trigger alerts to notify management for rapid response in case of issues.

2. Assembly Line Process Flow (Simplified Diagram)

Chassis Loading → Front/Rear Axle Installation → Powertrain Hoisting → Wheel Assembly Installation → Wiring & Electrical System Installation → Brake/Steering System Connection → Fluids Filling → Body Panels Installation (Cab/Cargo Box) → Interior & Seat Installation → Final Adjustment & Testing → End-of-Line & Warehousing

3. Our Core Advantages

- Modular Design: Lines can be flexibly configured and expanded based on customer capacity and factory layout.

- High Flexibility: Capable of mixed-model production for various three-wheeler types, with quick changeover of fixtures and jigs.

- Ergonomically Optimized: Scientifically designed workstations reduce operator fatigue and enhance assembly efficiency and safety.

- Technology Leadership: Incorporates proven Industrial Engineering principles and automation technology for reliable performance.

4. Success Applications

Our assembly lines have been successfully deployed for leading three-wheeler manufacturers globally, covering:

- Cargo Three-wheelers

- Passenger Three-wheelers

- Special Purpose Three-wheelers

Contact Us Today for Your Customized Three-Wheeler Assembly Line Solution!

Our expert team will tailor the most economical and efficient production solution based on your specific needs, helping you gain a competitive edge in the market.

How to set up a Tricycle Assembly Line factory?

Looking for VIN marking machines? Contact us for more information.

Need Filling Machines? Get expert support—request a quote or let’s talk about your project.

Looking for air compressors? Contact us for more information.

Need assembly tools or other auxiliary equipment? Contact us for more information.