Tractor Assembly Lines are suitable to Produce tractors. (If clients have more requirements, welcome to contact us.)

Introduction to Tractor Assembly Lines

Here is a detailed introduction to tractor assembly lines, covering their core concepts, main components, processes, technological trends, and significance.

I. Core Concept

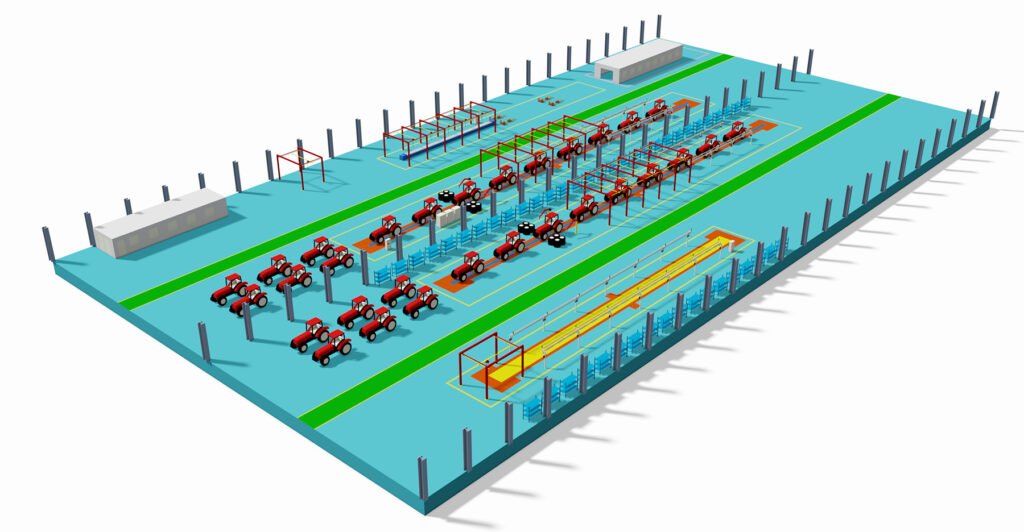

A tractor assembly line is a manufacturing system based on the principles of industrial conveyor production. It breaks down the entire assembly process of a tractor into a series of simple, standardized, and continuous workstations. Each station has specific tasks and a designated cycle time. The tractor chassis (frame) moves along a conveying device at a fixed pace. Workers install components step-by-step at stations along the line, resulting in a complete tractor rolling off at the end of the line.

II. Main Components (Customers can purchase the parts accordingly, some parts are optional)

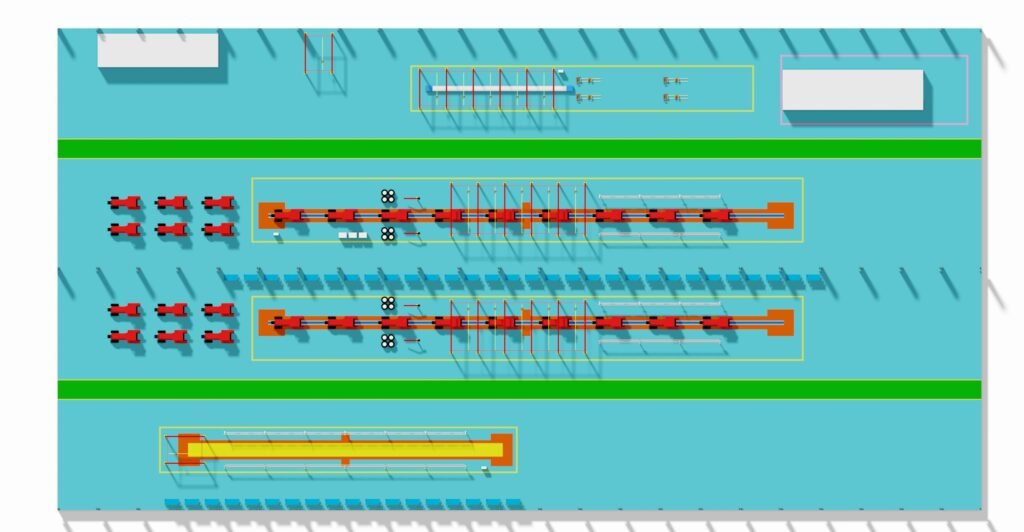

A modern tractor assembly line typically consists of the following key parts:

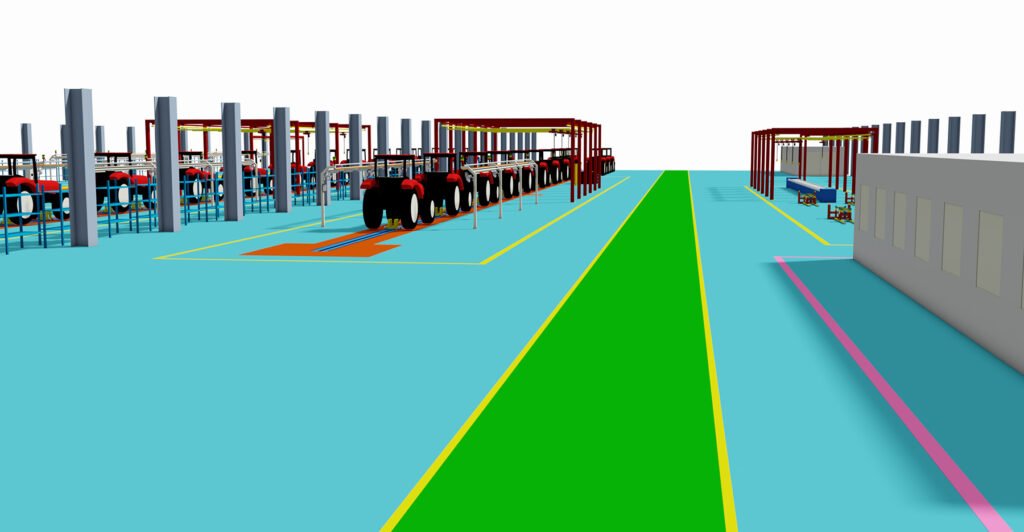

- Conveyance System:

- Main Line: Often uses slat conveyors to steadily move the heavy tractor chassis.

- Sub-assembly Lines/Feeder Lines: Used for pre-assembling large components like engines, front axles, cabs, and tires, which then merge with the main line.

- Overhead Conveyor Chains: Used for transporting components like cabs and fuel tanks.

- Workstations:

- Each station has clear work instructions, required tools, and parts racks.

- Equipped with torque tools, automatic fastening machines, marking machines, filling equipment, etc., to ensure consistent assembly quality.

- Material Supply System:

- SPS (Set Parts Supply) System: Based on the production schedule, all parts required for a specific workstation for one tractor are kitted together in advance and delivered synchronously to the line side via small carts.

- Kanban/Call Systems: Automatically send replenishment signals to the logistics center when line-side stock runs low.

- AGVs/AMRs (Automated Guided Vehicles/Autonomous Mobile Robots): Used for automatically transporting heavy or standardized material containers.

- Quality Control and Testing Stations:

- Critical stations have torque monitoring systems with real-time data upload.

- In-line Testing: Such as automatic filling and leak testing for brake fluid, coolant, and fuel.

- End-of-Line Testing: Final test stations conduct hub tests, light checks, emission tests, road simulation tests, etc.

- Information and Management Systems:

- MES (Manufacturing Execution System): Directs the entire production flow, tracking the status, process parameters, and quality data of each tractor.

- ANDON System: Allows workers to pull a cord to call for help if problems arise, enabling rapid management response.

III. Typical Assembly Process (Using a Medium-Sized Wheeled Tractor as an Example)

The process typically proceeds from back to front, with main stages as follows:

- Frame Loading and Pre-assembly: The frame is hoisted onto the main line, and components like air tanks and some wiring harnesses are installed.

- Rear Axle and Drivetrain Installation: Installation of the rear axle, transmission, and connection of the drive shaft.

- Engine Marriage: The pre-assembled engine unit is lowered and mated with the transmission—a critical “marriage” station.

- Front Axle Installation: Installation of the front axle and steering system.

- Hydraulics and Piping Installation: Installation of hydraulic pumps, control valves, hoses, and sometimes the cab.

- Tire Mounting: Installation of front and rear wheels (sometimes done at an earlier station).

- Cab Marriage: The complete cab unit is lowered onto the chassis.

- Filling and Electrical Connection: Filling of various fluids (engine oil, hydraulic oil, coolant) and connection of main electrical and pneumatic lines.

- Off-line Startup and Testing:

- First Startup: Battery charging and engine startup.

- PTO (Power Take-Off) Test, brake test, light test, water spray test for sealing, etc.

- Final Adjustments and Painting: Final inspection, minor adjustments, and application of final markings/paint.

- Finished Product Storage: Tested and approved tractors are driven to the finished goods warehouse, awaiting shipment.

IV. Modern Technological Trends

- Flexibility and Mixed-Model Production: A single line can accommodate different models and configurations (e.g., different horsepower, 2WD/4WD). The MES system automatically calls up the corresponding process.

- Automation and Robotics: Increasing use of robots for tasks like cab installation, windshield sealing, tire tightening, and heavy lifting—jobs that are highly repetitive or physically demanding.

- Digitalization and Industrial IoT (IIoT):

- Each component has a barcode/RFID, enabling full traceability.

- Use of Digital Twin technology to simulate and optimize the assembly process in a virtual space.

- Big data analytics to predict maintenance needs and quality risks.

- Human-Robot Collaboration: Collaborative robots (Cobots) work alongside workers to improve efficiency and safety.

- Green Manufacturing: Focus on energy saving, emission reduction, use of environmentally friendly paints, and waste reduction.

V. Significance

- Improves Efficiency: Standardized operations and parallel work significantly shorten production cycle times.

- Ensures Quality: Process standardization and in-line testing reduce human error, leading to more consistent quality.

- Reduces Costs: Economies of scale, reduced work-in-progress inventory, and optimized labor lower unit costs.

- Enhances Manageability: Production progress, material consumption, and quality data are transparent.

- Enables Rapid Market Response: Flexible production lines allow quicker adjustment of production plans to meet customer demands for personalized orders.

In summary, the modern tractor assembly line has evolved from a simple mechanical conveyor belt into a highly integrated, automated, digitalized, and intelligent complex manufacturing system. It is the core of large-scale, high-quality, and customizable tractor production, directly reflecting the technological level of the equipment manufacturing industry.

Characteristics of Tractor Assembly Lines

How to Select a Suitable Tractor Assembly Line

Find the Testing Line or Equipment for Your Needs. Get expert support—request a quote or let’s talk about your project.

Need Coating Line or Coating Equipment? Get expert support—request a quote or let’s talk about your project.

Looking for VIN marking machines? Contact us for more information.

Need Filling Machines? Get expert support—request a quote or let’s talk about your project.

Looking for air compressors? Contact us for more information.

Need assembly tools or other auxiliary equipment? Contact us for more information.