How to Select a Suitable Tractor Assembly Line

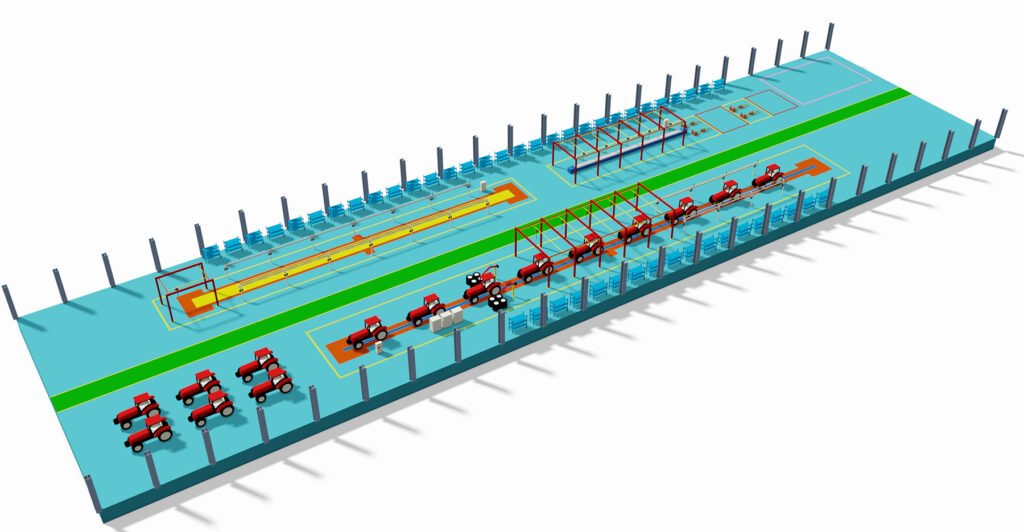

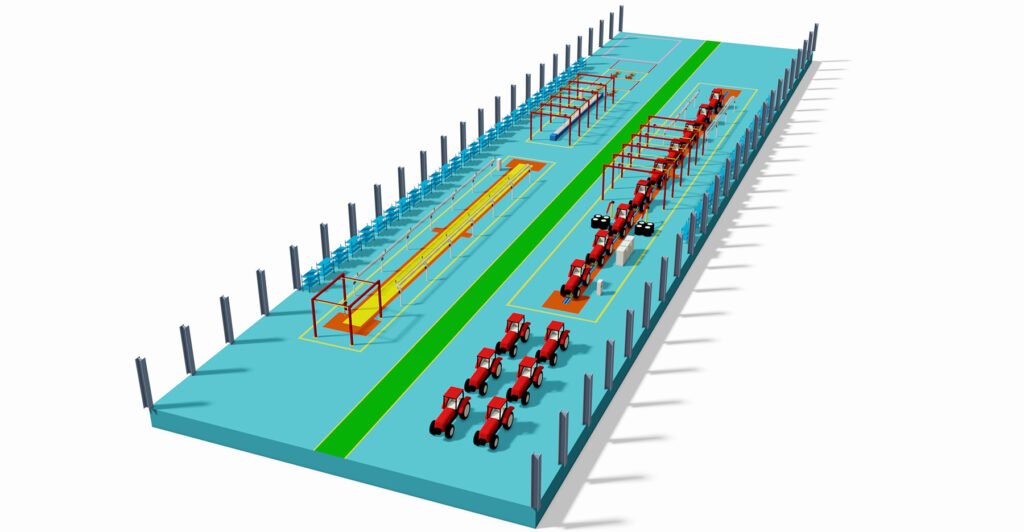

Tractor Assembly Lines are suitable to Produce tractors. (If clients have more requirements, welcome to contact us.)

Step 1: Define Core Prerequisites

Before considering specific equipment, three fundamental questions must be clarified:

- What is the product? Define the type of tractor to be produced (e.g., small-to-medium horsepower general-purpose, high-horsepower heavy-duty, specialized orchard models), the power type (fuel, electric), future product plans, and the degree of customization required.

- What is the target output? Determine the target annual and shift production volumes for both the present and the coming years, from which the required production takt time can be derived.

- What is the budget? Plan the total investment budget, covering equipment, civil construction, software, and ongoing maintenance.

Step 2: Determine the Assembly Line Configuration Level

Based on the above prerequisites, assembly lines can generally be categorized into three configuration tiers:

- Basic/Economical Type: Suitable for scenarios with single product type, large batch sizes, and limited budget. It typically uses fixed-takt floor drag chains or plate chains, relies on manual assembly and paper-based instructions, logistics depend on forklifts, and inspection is mostly performed offline.

- Standard/Flexible Type: Suitable for multiple product varieties and small-to-medium batch production with conventional upgrade needs. It employs adjustable-speed power-and-free lines (e.g., friction drive). Critical workstations are equipped with torque-controlled tools with data recording, electronic work instructions are used, logistics employ kanban or set-parts supply, and key inspections (e.g., brake and light testing) can be integrated into the line.

- High-end/Intelligent Type: Suitable for goals of digital transformation involving high complexity, multiple product categories, and a high degree of customization. It utilizes highly flexible AGV or skid lines, enabling modular layout and dynamic path planning. Tool data is networked throughout the entire process, AR-assisted assembly is applied, logistics are handled by AGV automated delivery, and full-process online inspection with real-time quality data analysis is achieved, managed and traced in-depth by an MES system.

Step 3: Evaluate Key Technologies and Select Suppliers

Once the direction is clear, a deeper evaluation is needed:

- Core Technologies: Focus on the load capacity and reliability of the conveying system, the precision and traceability of tightening tools, the sophistication of testing equipment, and the integration level of the information system (MES).

- Supplier Selection: Prioritize suppliers with proven success cases in the tractor or heavy machinery industry. Assess whether they possess process planning capabilities beyond just equipment manufacturing, and evaluate their strength in localized service, spare parts supply, and providing turnkey solutions.

Step 4: Adhere to Core Decision-Making Principles

- Process Dictates Equipment: Detailed process planning must come first; equipment should then be selected based on process requirements. Avoid putting the cart before the horse.

- Pursue Human-Robot Collaboration: Prioritize automation in areas like heavy load handling, precision tightening, and repetitive testing, while retaining the advantages of human labor in complex wiring, debugging, etc.

- Plan for Future Expansion: Design must inherently consider the flexibility and scalability needed for future capacity increases or new product introductions.

- Calculate Total Cost of Ownership (TCO): Comprehensively evaluate initial investment, energy consumption, maintenance, downtime costs, and upgrade expenses, not just the purchase price.

In summary:

- Enterprises with a single product type can start with a Standard Flexible Line to ensure quality control.

- Mainstream manufacturers should invest in a deeply integrated, flexible line as the core of their digital transformation.

- Enterprises producing extra-large horsepower or special models might be better suited to an “Fixed Station + AGV Carrier” assembly cell mode for maximum flexibility.