How to Establish a Motorcycle Assembly Line Factory?

Motorcycle Assembly Lines are suitable to Assemble/Produce 2 wheel Motorcycles, 2 wheel Scooters, 2 wheel Electric-cycles, 2 wheel E-Bikes, Bicycles, Bikes, and so on. (Sometimes, suitable for the production of Tricycles.)

How to Establish a Motorcycle Assembly Line Factory?

Phase 1: Strategic Planning and Feasibility Analysis (Preparatory Stage)

This is the most critical step.

- Market Research and Positioning:

- Target Market: Who are you producing for? Commuting, recreation, or the high-performance market?

- Product Positioning: What type of motorcycles will you produce? Scooters, street bikes, off-road bikes, or cruisers?

- Competitor Analysis: Understand the prices, sales volumes, strengths, and weaknesses of existing brands.

- Demand Forecast: Predict future sales volume and growth potential based on market data.

- Business Plan:

- Financial Planning: Estimate in detail the startup capital (land, factory building, equipment, raw materials, labor), operating costs, expected revenue, and profit cycle.

- Funding Sources: Determine if it will be self-funded, through bank loans, or by seeking investors.

- Business Model: Will it be Original Brand Manufacturing (OBM), Original Equipment Manufacturer (OEM), or Original Design Manufacturer (ODM)?

- Technology and Partnerships:

- Technology Source: Will you purchase mature technical licenses (e.g., partnering with a foreign brand) or conduct independent research and development?

- Key Partners: Find reliable suppliers for core components like engines, frames, and ECUs.

Welcome to contact us for more information of Motorcycle Components.

Phase 2: Factory Construction and Supply Chain Setup

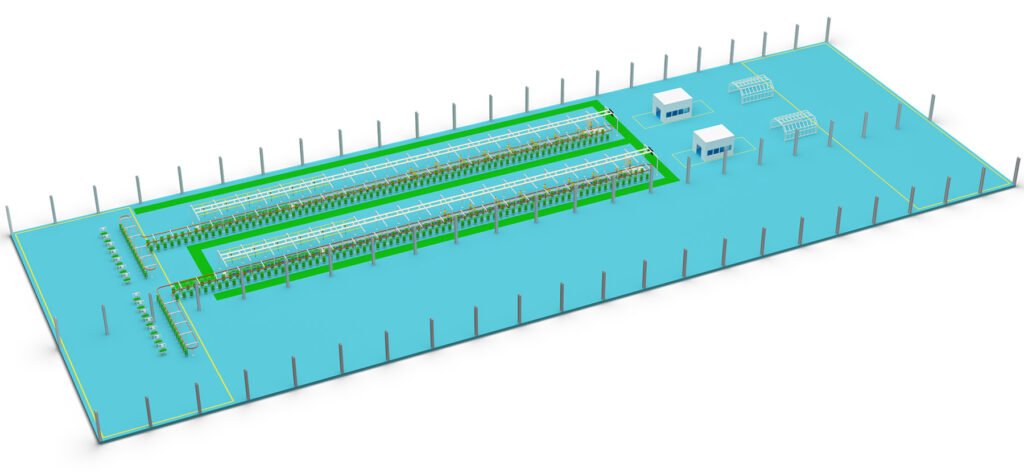

- Site Selection and Land/Factory Building:

- Geographical Location: Prioritize industrial parks close to the target market, with convenient transportation (near ports, highways), and a well-developed supporting supply chain.

- Policy Support: Investigate local tax incentives, land, and policy benefits.

- Infrastructure: Ensure water, electricity, gas, internet, and other infrastructure are complete.

- Factory Requirements: Design the factory layout according to the production scale, including receiving area, warehouse, production line, quality inspection area, testing area, finished product warehouse, etc.

- Supply Chain System Establishment:

- Core Components: Identify suppliers for key parts like engines, frames, suspension, brakes, and tires, and sign long-term contracts.

- Secondary Components: Establish a supply network for electronic components, wiring harnesses, lights, plastic parts, and standard parts (screws, nuts).

- Supply Chain Management: Establish strict supplier audits (quality, delivery time, price) and inventory management systems (e.g., Just-in-Time production).

Phase 3: Assembly Line Design and Equipment Procurement

This is the core of the “assembly line.”

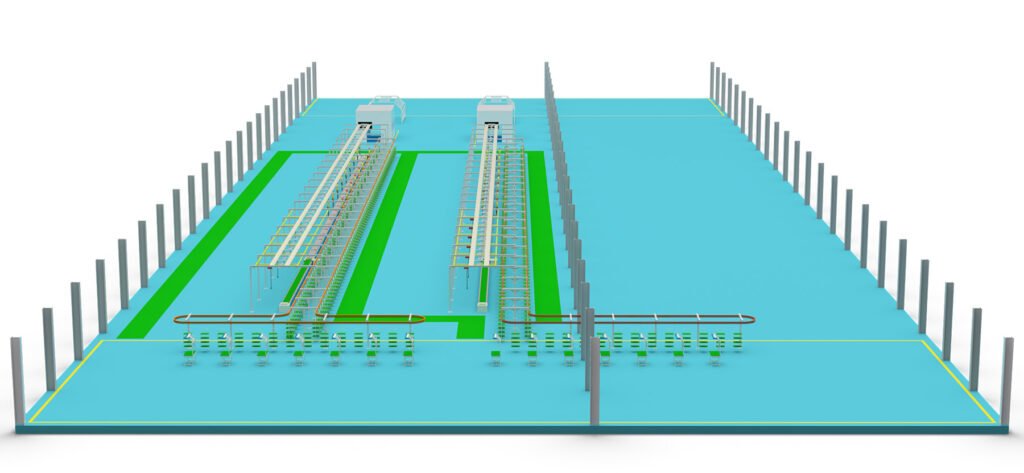

- Production Process Design:

- Break down motorcycle assembly into several logical steps. A typical process is:

- Frame hoisting onto the line

- Install rear suspension, engine

- Install front fork, wheels

- Install fuel tank, seat

- Install wiring harness, ECU, instrument panel

- Install exhaust system

- Fill with fluids (engine oil, brake fluid, coolant)

- Install body panels, lights

- Final debugging and inspection

- Road test and packaging

- Break down motorcycle assembly into several logical steps. A typical process is:

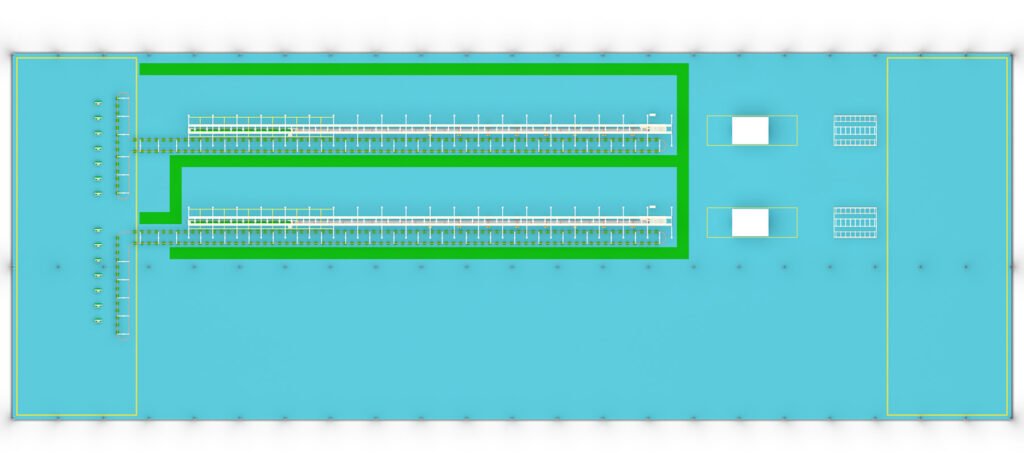

- Assembly Line Layout:

- Type Selection:

- Assembly Line: Uses a conveyor belt; vehicles move at a constant speed, and workers perform tasks at fixed stations. High efficiency, suitable for large-scale standardized production.

- Cellular Manufacturing: Vehicles are at fixed stations, where a small team completes most of the assembly work. High flexibility, suitable for small-batch, multi-variety production.

- Layout Planning: Design material distribution routes to ensure parts can be delivered to corresponding stations efficiently and accurately.

- Type Selection:

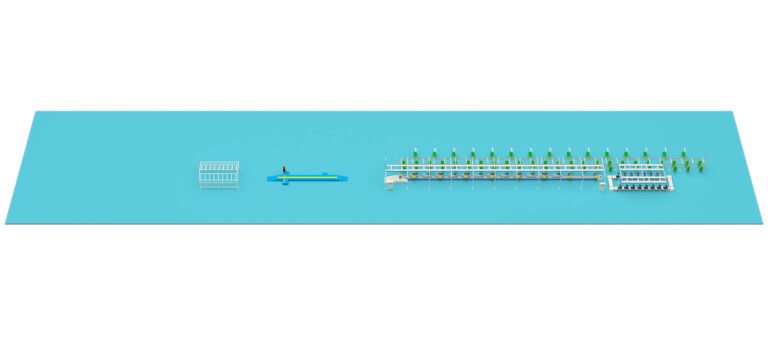

- Equipment and Tool Procurement:

- Basic Equipment: Conveyor belts, lifting platforms, vehicle support stands.

- Tools: Pneumatic/electric wrenches, torque wrenches, screwdrivers, pliers, measuring instruments.

- Professional Equipment: Engine hoists, wheel balancers, headlight testers, brake test benches, chassis dynamometers, emission analyzers.

- Fluid Filling Equipment: Vacuum filling machines for engine oil, brake fluid, coolant.

- Information Systems: MES (Manufacturing Execution System) for tracking production progress and quality data.

Welcome to contact us for more information of Auxiliary Equipment: testing line, air compressor, filling equipoment, tools or others.

Phase 4: Team Building and Quality Management

- Organizational Structure and Recruitment:

- Management Team: Factory General Manager, Production Manager, Quality Manager, Procurement Manager, etc.

- Technical Team: Process Engineers, Maintenance Engineers, Quality Inspectors.

- Production Team: Line Supervisors, Assembly Workers.

- Other Functions: Warehouse, Logistics, Administration, Finance personnel.

- Training System:

- Standardized Work: Develop detailed work instructions for each station.

- Skills Training: Includes tool use, torque management, quality standards, and safety regulations.

- Ongoing Training: Regular training for new models and new processes.

- Quality Assurance System:

- Establish Standards: Develop a full set of inspection standards from component arrival to finished vehicle output.

- Process Control:

- IQC (Incoming Quality Control): Inspect incoming components.

- PQC (Process Quality Control): Set up quality checkpoints at key stations.

- FQC/OQC (Final/Outgoing Quality Control): Perform 100% inspection and road tests on finished vehicles.

Phase 5: Production Launch and Continuous Improvement

- Trial Production and Debugging:

- Use small batches of materials to debug the production line, verifying equipment, processes, and personnel training.

- Produce the first pilot vehicles for rigorous testing and evaluation.

- Official Production and Ramp-up:

- Start formal production, gradually increasing the production tempo until the designed capacity is reached.

- Closely monitor and promptly resolve issues during production.

- Continuous Improvement:

- Introduce lean manufacturing concepts such as 5S, Kanban systems, and waste elimination to continuously optimize processes, improve efficiency, and reduce costs.