Characteristics of an Automotive Assembly Line–Characteristics of an Automotive Production Line

Automobile Assembly Lines are suitable to Produce 4 wheelers, Cars, Sedans, SUVs, Automobiles, EVs, Mini Vans, Hybrid Models and so on. (Sometimes, suitable for the production of pickups.)

Characteristics of an Automotive Production Line

An automotive production line is one of the most complex, automated, and highly integrated production systems in industrial manufacturing. Its core characteristics can be summarized as follows: guided by the philosophy of “lean production,” driven by “high automation,” and empowered by “high flexibility” to adapt to changes, ultimately achieving large-scale output of high-quality products.

Here is a detailed breakdown of the main characteristics of automotive production lines:

1. High Automation and Intelligence

- High Robot Density: In processes such as welding, painting, and stamping, the utilization rate of robots can exceed 90%, performing tasks that are high-intensity, high-precision, or hazardous (e.g., welding, painting).

- Data-Driven Operations: The production line is deeply integrated with Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP), collecting real-time data on production, quality, and equipment status to enable full-process traceability and intelligent decision-making.

- Industrial Internet of Things (IIoT): Interconnected devices facilitate predictive maintenance, reducing unplanned downtime.

2. Strict Pacing and Flow Production

- Fixed Cycle Time: The entire production line operates on a fixed time cycle (e.g., 60 seconds per vehicle). Each workstation must complete its tasks within this cycle to ensure smooth and efficient flow.

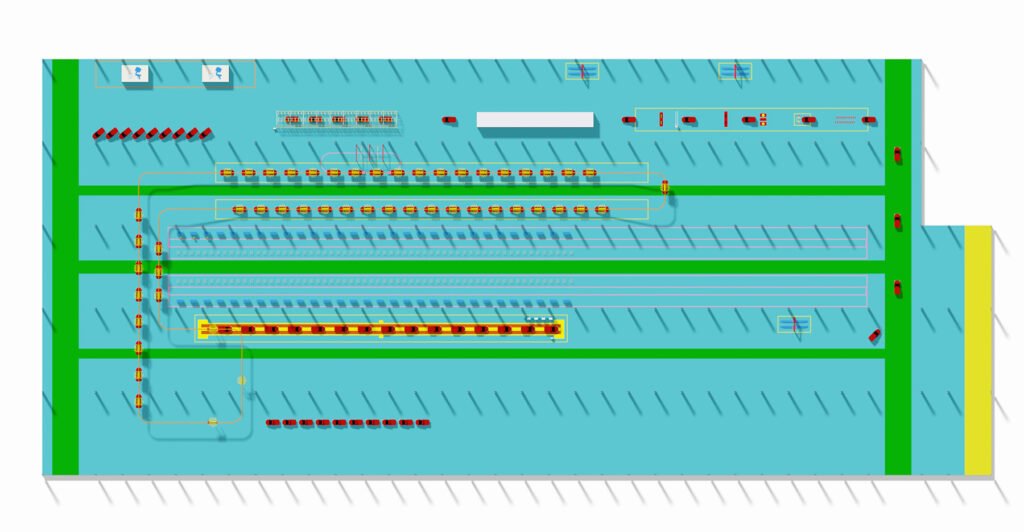

- Flow Line Layout: Materials and vehicle bodies move along precisely calculated paths and speeds, progressing sequentially through all process steps from a sheet of steel to a finished vehicle.

3. High Flexibility in Production Capacity

- Mixed-Model Production: A single assembly line can simultaneously produce different models (sedans, SUVs), powertrains (ICE, hybrid, electric), and configurations. This is key for modern automakers to respond to market diversification.

- Modular Design: Vehicles are broken down into modules (e.g., front-end module, cockpit module, rear floor module) for pre-assembly on sub-lines before precise final assembly on the main line. This improves efficiency and quality while enabling flexibility.

4. “Lean Production” Philosophy Throughout

- Just-in-Time (JIT) Production: Components are delivered directly to the line-side workstation in the exact sequence and timing required for production, minimizing inventory.

- Kanban Management: Physical or electronic Kanban systems pull production and material supply from upstream processes, preventing overproduction.

- Andon System: Any abnormality (quality, material, or equipment issue) at a workstation triggers an “Andon” alert, prompting immediate management response to resolve the issue.

5. Stringent Quality Control System

- Full-Process Inspection: Multiple quality gates exist, from stamping part inspection, welding body-in-white precision measurement (CMM), and paint film inspection to final assembly checks such as electrical function tests, wheel alignment, light testing, road tests, and water leakage tests.

- Andon Authority: Any employee has the authority to stop the production line upon detecting a quality issue, ensuring defects do not pass to the next station.

- Automated Inspection: Widespread use of machine vision and sensors for automated checks (e.g., gap and flush measurements, assembly completeness).

6. Close Coordination Among Four Core Processes

- Stamping: Characterized by high tonnage, precision, and efficiency. Transforms steel sheets into body panels. Dies are critical, with a focus on “multiple parts per die” and quick die changes.

- Welding: Highest automation rate (up to 99%). Joins hundreds of stamped parts into a body-in-white using spot welding, laser welding, etc. Heavy use of robots ensures welding strength and body accuracy.

- Painting: Most complex process with the strictest environmental requirements (dust-free, constant temperature, and humidity). Includes pre-treatment, electrophoretic coating, primer, color coat, and clear coat. Focuses on corrosion resistance and aesthetic appeal, with emphasis on environmental protection and energy consumption.

- Final Assembly: Relatively labor-intensive and requires the highest flexibility. Assembles the engine, chassis, interior, and electronic systems onto the body. Extensive use of human-robot collaboration, assistive devices, and Automated Guided Vehicles (AGVs).

7. Strong Dependence on and Efficient Integration with the Supply Chain

- Synchronized Logistics: The supply chain is deeply aligned with the OEM’s production schedule, enabling precise “door-to-line” material delivery.

- Modular Supply: Suppliers deliver pre-assembled large modules (e.g., instrument panel module, front-end module) for direct installation by the OEM, simplifying final assembly.

In summary, an automotive production line is a highly coordinated, precisely operated, and continuously evolving complex mega-system. It not only reflects the strength of the automotive industry but is also a crown jewel of modern manufacturing.