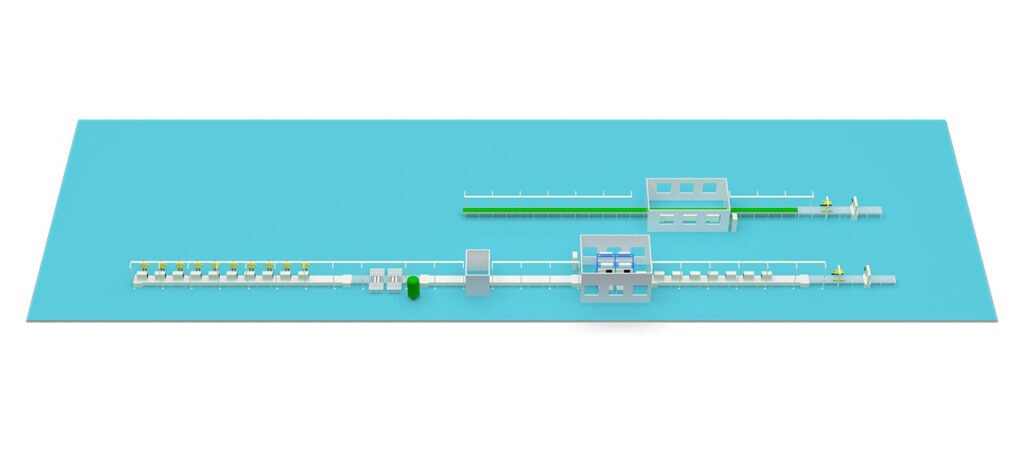

Air Conditioner Assembly Lines/Production Lines are Suitable to Assemble/Produce Air Conditioners.(Welcome to contact us, we will suggest and design the suitable Assembly Lines/Production Lines for your Air conditioners.)

1. Core Characteristics of Air Conditioning Assembly Lines

Different from general home appliances, air conditioning assembly lines have their unique features:

- “Two Heat Exchangers” First: The production of the condenser and evaporator (the two heat exchangers) is usually an independent pre-process before they are brought onto the assembly line.

- Extremely High Sealing Requirements for the Refrigerant System: Involves critical quality control points such as nitrogen charging and leak testing, vacuum pumping, and refrigerant charging.

- Separate Assembly for Indoor and Outdoor Units: Typically, there are two parallel final assembly lines, with units eventually matched and packaged together.

- Mixed-Model Production for Multiple Variants: One line needs to flexibly adapt to different models and capacities of air conditioners.

2. Main Process Flow (Using a Split-Type Air Conditioner as an Example)

A. Indoor Unit Assembly Line

- Housing Loading: Injection-molded panels and bases are loaded onto the line.

- Labeling and Component Installation: Applying electrical labels and nameplates, installing air deflector motors, stepper motors, etc.

- Heat Exchanger Installation: Installing the evaporator assembly into the housing and connecting the piping.

- Fan Motor and Cross-flow Fan Installation: A key control point for indoor unit noise, requiring dynamic balancing testing.

- Electrical Control Box Installation: Installing components like PCBs and capacitors into the electrical control box, then installing the entire box into the unit.

- Electrical Connection and Functional Testing: Connecting all wiring harnesses and conducting power-on tests (e.g., indicator lights, louvers, motor operation).

- Filter Installation.

- Final Visual Inspection and Cleaning.

- Packing and Palletizing.

B. Outdoor Unit Assembly Line

- Chassis Loading: Stamped chassis are loaded onto the line.

- Compressor Installation: This is the “heart” of the outdoor unit, requiring torque-controlled wrenches to ensure proper tightness.

- Condenser Installation: Mounting the condenser assembly onto the chassis.

- Pipe Brazing/Welding: This is one of the most critical and challenging steps to automate. Connecting the compressor, condenser, four-way valve, etc., with copper pipes using brazing with nitrogen purging to prevent oxidation.

- Nitrogen Charging and Leak Testing (Pressure Holding): Charging the welded system with high-pressure nitrogen to check all brazed joints for leaks. This is a critical quality gate.

- Fan and Motor Installation: Installing the axial fan and outdoor motor.

- Electrical Control Box Installation and Wiring.

- Vacuum Pumping and Refrigerant Charging: Evacuating the system to a high vacuum, then precisely charging it with a specified amount of refrigerant (R32, R410A, etc.). This is a core process point requiring extremely high precision.

- Final Performance Testing (Testing Room): Testing comprehensive performance under simulated conditions (cooling/heating capacity, power consumption, current, pressure, noise, etc.). Non-conforming units enter the rework line.

- Casing Installation and Labeling.

- Packing and Palletizing.

3. Key Technologies and Automation Applications

- Automated Brazing/Welding: Robotic arms automatically braze copper pipes, improving consistency, though less flexible and better suited for high-volume models.

- Automatic Screwdriving Machines: Automatically drive screws at multiple stations, ensuring torque and recording data for traceability.

- AGV/Roller Conveyor Logistics: Using AGVs to automatically deliver large components like compressors and heat exchangers to the line-side.

- Robotic Gluing and Assembly: e.g., automatic application of sealant for outdoor unit casings, automatic press-fitting of fans.

- Automatic Inspection Technology:

- Machine Vision: Inspects labels, surface scratches, missing components.

- Laser/Ultrasonic Leak Detection: Higher precision, more environmentally friendly leak detection methods, replacing traditional water immersion testing.

- Automatic Performance Test Benches: Computer-controlled, automatically collecting data and determining pass/fail status.

- MES (Manufacturing Execution System): Tracks material batches, process parameters, and test data for each unit, enabling full lifecycle traceability.

Summary

A modern air conditioning assembly line is a complex system integrating precision machinery, fluid control, electrical engineering, and information technology. It is evolving from a traditional rigid conveyor belt into an intelligent production line characterized by data transparency, controllable processes, and flexibility. The core goal remains to improve efficiency, reduce costs, and respond quickly to market changes while ensuring extremely high sealing integrity and reliability.

How to set up a AC(Air Conditioner) Assembly Line factory?

Find the Testing Line or Equipment for Your Needs. Get expert support—request a quote or let’s talk about your project.

Need Coating Line or Coating Equipment? Get expert support—request a quote or let’s talk about your project.

Looking for VIN marking machines? Contact us for more information.

Need Filling Machines? Get expert support—request a quote or let’s talk about your project.

Looking for air compressors? Contact us for more information.

Need assembly tools? Contact us for more information.