Characteristics of Tractor Assembly Lines—-What are the Characteristics of Tractor Assembly Lines?

Tractor Assembly Lines are suitable to Produce tractors. (If clients have more requirements, welcome to contact us.)

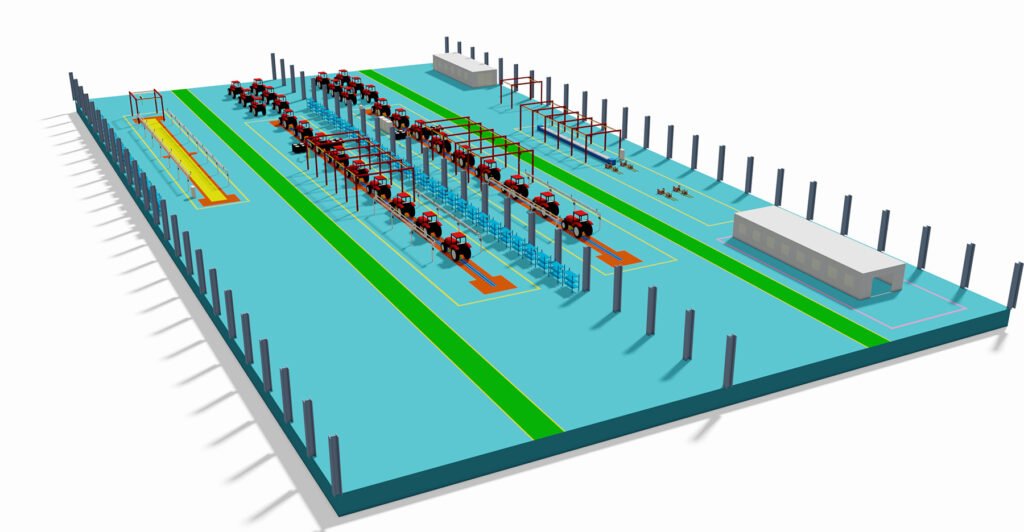

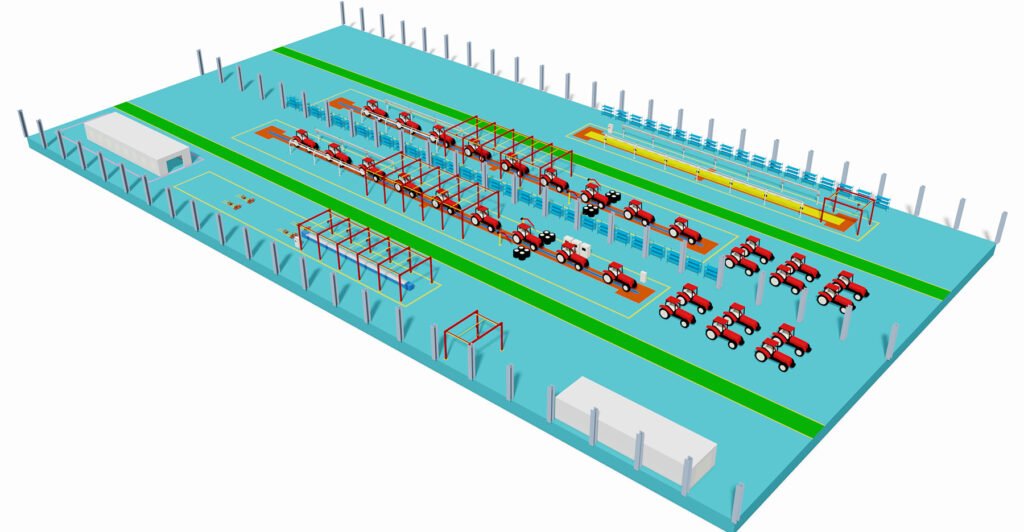

As a core component of agricultural machinery manufacturing, tractor assembly lines exhibit the following distinctive features:

1. Modular and Flexible Design

- Modular Workstations: Key components such as engines, drivetrains, cabins, and tires are assembled in independent modules, facilitating parallel operations and quality control.

- Flexible Adaptability: Capable of accommodating different horsepower ranges, configurations (e.g., wheeled/crawler), and customized variants (e.g., orchard or paddy field models) by adjusting fixtures and process flows.

2. Hybrid Flow Line Layout

- “Chassis-Guided” Flow: The chassis, mounted on a pallet, moves along rails, with components assembled sequentially.

- Human-Robot Collaboration: Heavy components (e.g., engines, counterweights) are handled by assistive manipulators or cranes, while precision tasks (e.g., hydraulic/pipeline and electrical circuit integration) rely on manual fine-tuning.

3. Integration of Heavy-Duty and High-Precision Requirements

- Specialized Load-Bearing Design: Conveyor lines must support entire machines weighing several to tens of tons while providing anti-drift positioning.

- Precision Assembly Demands: Critical processes (e.g., gearbox mating, front/rear axle alignment) employ laser calibration or hydraulic servo systems to ensure micron-level accuracy.

4. Multi-System Integration and Testing

- In-Line Testing Integration: Processes like brake testing, light alignment checks, and hydraulic sealing tests are embedded into the main line, forming a closed loop of “assembly-test-correction.”

- Data Traceability Systems: RFID or QR codes are used to link vehicle information, recording component sources, torque data, and inspection results for full lifecycle management.

5. Adaptation to Complex Process Chains

- Multi-Disciplinary Integration: Covers composite processes including mechanical assembly, hydraulic pipeline routing, electrical control system wiring, and paint touch-ups.

- Dynamic Cycle Time Control: Adjusts line-side inventory and process sequencing based on component supply conditions (e.g., large sheet metal parts, imported engines).

6. Environmental and Safety Specificities

- Heavy-Duty Environment Design: Special requirements such as reinforced flooring, wide tool passages, and explosion-proof electrical systems (e.g., for fuel filling stations).

- Ergonomic Optimization: Equipped with lifting platforms and rotating fixtures to minimize strenuous postures like bending or overhead work.

In essence, tractor assembly lines represent a fusion of heavy machinery discrete manufacturing and flow production. The core challenge lies in balancing standardized efficiency with the diverse variants of agricultural machinery. With the growing adoption of electrification and smart implement interfaces, assembly lines are evolving further into reconfigurable intelligent manufacturing systems.