Automotive Testing Line—Pre-delivery Vehicle Final Inspection—Test Equipment

Automobile Test Lines are suitable to Test Cars, Sedans, SUVs, Automobiles, EVs, Mini Vans, Hybrid Models and so on. (Welcome to contact us, we will suggest you more suitable solution)

Pre-delivery Vehicle Final Inspection is the final and most comprehensive quality gate a vehicle must pass after completing all assembly on the production line, before being delivered to the customer. It ensures the vehicle is not only fully assembled but also that all its functions, performance, and safety systems are compliant with design standards.

This stage is commonly known as the “End of Line” or “EOL Test.”

1. Explanation of Core Inspection Stages

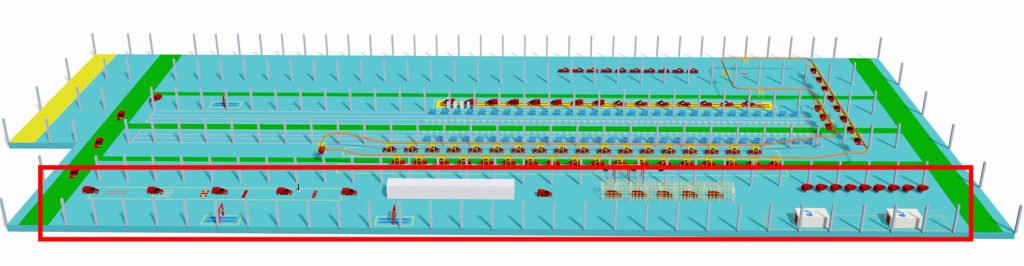

1.1 Comprehensive Vehicle Test Line (Dynamic & Electronic Systems)

The vehicle enters a dedicated test lane integrated with various inspection equipment.

- Wheel Alignment & Headlight Calibration

- Purpose: Ensure stable straight-line driving, precise steering, and even tire wear.

- Method: The vehicle drives onto an aligner. Sensors automatically clamp onto the wheels to measure and adjust parameters like toe and camber. Simultaneously, the equipment calibrates the cut-off height and angle of low and high beams to ensure regulatory compliance and prevent glare for oncoming traffic.

- Chassis Comprehensive Check

- Purpose: Inspect the fastening status of underbody components, and identify any abnormal noises, interference, or leaks.

- Method: The vehicle passes over an area with rollers and lifting devices, or is placed on a lift. Technicians visually inspect the installation of underbody lines, the exhaust system, and suspension components. A “shaker” test might be performed to check steering and suspension.

- Dynamometer / Roller Test

- This is one of the most core and technically sophisticated tests at EOL.

- Purpose: Simulate real road conditions to comprehensively validate the powertrain, braking system, drivetrain, and in-vehicle electronic networks without moving the vehicle.

- What is checked:

- Engine & Transmission: Check for smooth operation and abnormal noises across different engine RPM ranges at various simulated “speeds,” and ensure accurate, smooth gear shifts.

- Braking Performance: Test the braking force of each wheel and the balance between left and right sides to ensure safe and effective braking.

- Speedometer Calibration: Ensure the displayed speed matches the actual speed.

- ABS/ESP/EBD, etc.: Trigger these systems by simulating a wheel “lock-up” (slowing a roller) and confirm their correct operation via dashboard warning lights and backend data.

- Vehicle Network Communication: During the test, all ECUs engage in high-speed network communication (CAN/LIN bus) to detect any communication fault codes.

- Initial Emission Check: Connect an exhaust gas analyzer to check if emissions at idle and under simulated driving conditions meet standards (more stringent testing is done in specialized labs).

1.2 Vehicle Sealing Tests

- High-Pressure Water Leak Test

- Purpose: Simulate extreme storm conditions to test the vehicle’s sealing from all angles.

- Method: The vehicle enters a sealed chamber and is subjected to multi-directional, high-pressure water jets from above, the sides, and below at an intensity far exceeding natural rainfall (typically for several minutes). Afterwards, inspectors check the interior, trunk, door seals, sunroof, etc., for any signs of water ingress or leaks.

1.3 PDI Lighting Corridor

Inspection Stations: Vehicles pass slowly or stop at designated spots for inspectors to examine from all angles.