Fridge Assembly Line—How to Set a Fridage Assembly Line Factory?—what is a Fridge Assembly Line?

Fridge Assembly Lines/Production Lines are Suitable to Assemble/Produce Fridges.(Welcome to contact us, we will suggest and design the suitable Assembly Lines/Production Lines for you.)

Establishing a modern refrigerator assembly line factory is a systems engineering project, encompassing the entire process from strategic planning to operational implementation. The following is a phased, systematic detailed guide, integrating the core principles of industrial engineering, lean manufacturing, and smart manufacturing.

Phase 1: Top-Level Strategy and Planning (Project Initiation and Design)

This is the foundation that determines the project’s success and requires significant effort in research and design.

- Market and Product Definition

- Product Positioning: Determine which types of refrigerators to produce (French door, multi-door, side-by-side, compact freezers?), target market (premium, mid-range, economy?), and projected annual capacity (e.g., 500,000 units/year).

- Technology Roadmap: Define core technologies, such as compressor suppliers, refrigerant type (e.g., R600a), foaming technology, and level of smart features. This will directly impact equipment selection.

- Factory Role: Is it a final assembly plant (purchasing most components) or an integrated plant (producing doors, cabinets, liners in-house)? The latter requires massive investment but offers greater control.

- Site Selection and Layout Planning

- Site Selection Criteria:

- Supply Chain Proximity: Close to suppliers of sheet metal, plastic parts, compressors, and electronic components.

- Logistics Advantage: Near ports, highways for efficient inbound materials and outbound finished goods.

- Policy and Cost: Consider land, taxes, energy (stable and low-cost electricity), and labor resources.

- Layout Design (Core):

- General Principle: Optimize material flow, minimizing crossovers, backtracking, and waiting.

- Typical Layout: U-shaped or straight-line. The mainstream trend involves several specialized workshops/areas:

- Sheet Metal Stamping and Painting Workshop (if producing cabinets in-house)

- Plastic Parts Molding Workshop (if producing liners, door inners in-house)

- Sub-Assembly Area (door foaming pre-assembly, drawer modules, electrical box pre-assembly)

- Main Final Assembly Line (core)

- Foaming Area (core process, requires isolation)

- Performance Testing and Packaging Area

- Logistics Design: Plan material delivery routes (AGVs, tow trains, conveyors), establish central warehousing and line-side supermarkets.

- Site Selection Criteria:

- Investment Budget and Financial Analysis

- Detailed costing: Land & building, production line equipment, utilities (power distribution, compressed air, chilled water), environmental systems, IT systems, working capital, etc.

- Evaluate the return on investment (ROI) period.

Phase 2: Core Assembly Line Process Design

The core of refrigerator assembly is the sequence: “Cabinet Forming → Liner Installation → Foaming → Final Assembly → Testing.”

- Cabinet Forming and Pre-treatment Line (if produced in-house):

- Process: Steel coil uncoiling → Stamping (cabinet shell, door shell) → Bending → Welding → Pre-treatment (degreasing, phosphating) → Powder coating → Curing.

- Liner Forming Line (if produced in-house):

- Process: Plastic pellets (ABS/HIPS) → Vacuum forming → Trimming → Welding (liner corners) → Punching.

- Door Foaming Sub-Assembly Line:

- Process: Door shell + door liner + handles/other attachments → Load into foaming mold → Inject polyurethane (PU) foam → Curing → Demolding → Install hinges, door gaskets, etc. This is a critical area independent of the main line.

- Main Cabinet Assembly Line (Core Process Flow):

- Station 1: Cabinet Loading. Install feet, rating plate.

- Stations 2-4: Install Internal Components. Mount the evaporator (often a pre-made module), condenser tubing, drain pipe, etc., into the back or interior of the cabinet.

- Station 5: Install Liner. Place the plastic liner into the cabinet shell and secure it.

- Station 6: Key Process – Cabinet Foaming. Push the cabinet into a large foaming mold, inject PU foam to fill the cavity between the shell and liner, forming the insulation layer. Requires strict temperature control, material ratio, and dwell time.

- Station 7: Curing and Cleaning. Post-foaming curing and removal of excess flash (“deflashing”).

- Station 8: Install Compressor. This is the heaviest component, typically using assistive robotic arms.

- Station 9: Install Electrical System. Mount the control board, wiring harnesses, light, thermostat, etc.

- Station 10: Evacuation & Refrigerant Charging. Connect to service ports, evacuate using professional equipment, and charge with precise amount of refrigerant. This is a core quality control point.

- Station 11: Install Rear Panel. Attach the back cover, enclosing internal components.

- Station 12: Install Doors. Mount the pre-assembled doors to the cabinet via hinges and adjust gaps.

- Testing and Packaging Line:

- Performance Testing: Power on for burn-in/baking (typically 12-24 hours), testing cooling capacity, temperature uniformity, noise, energy consumption, etc. This is the most critical quality gate.

- Final Inspection: Visual, functional, and safety checks.

- Cleaning and Packaging: Clean, apply protective film, insert accessories & manual, bag, and carton.

Phase 3: Equipment Selection and Systems Integration

- Core Process Equipment:

- Foaming Equipment: High-pressure foaming machines, foaming molds (cabinet, door), curing conveyors. This is one of the most expensive and technologically intensive investments.

- Refrigerant Charging Equipment: High-precision automatic charging stations.

- Evacuation Equipment: Multi-station automatic vacuum systems.

- Assembly Equipment: Automatic screwdrivers/torque tools (for critical points like compressor, hinges), assistive robotic arms, automatic marking/labeling machines.

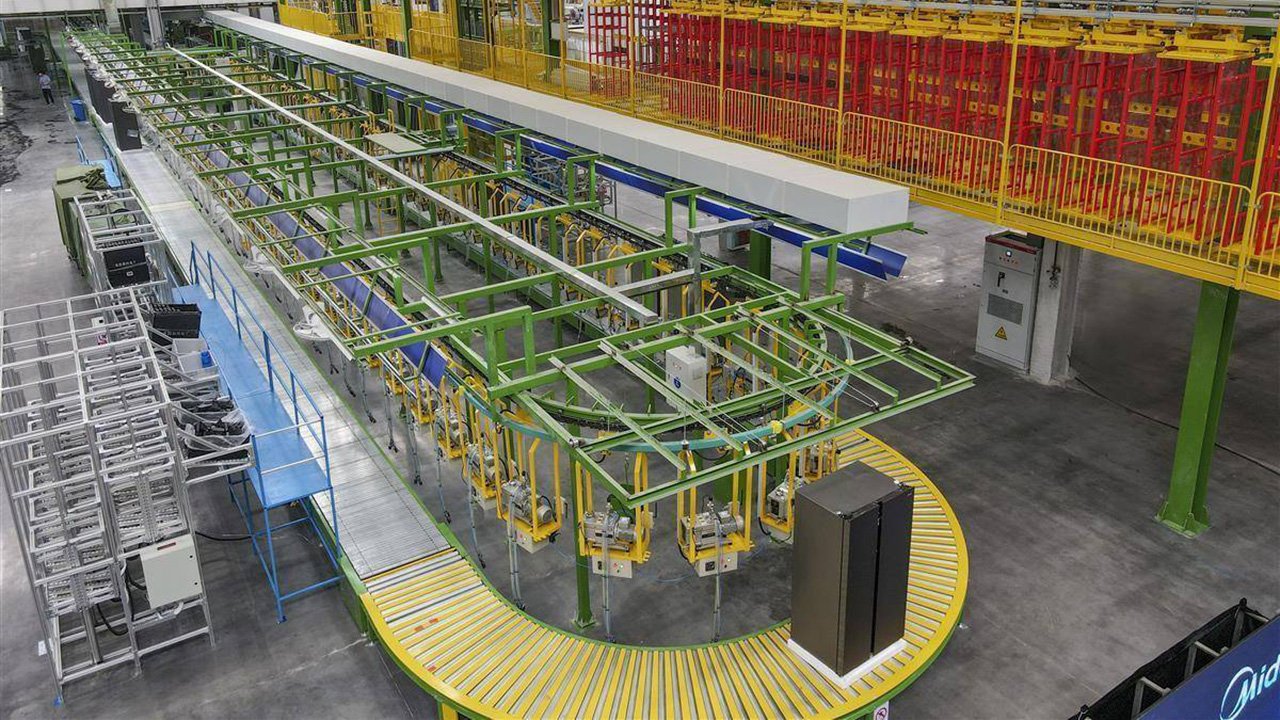

- Conveyance Systems: Friction roller conveyors, power & free chains, slat conveyors, lifters, AGVs.

- Testing Equipment: In-line leak detectors, helium mass spectrometer leak detectors (premium), performance test chambers, noise test rooms.

- Information Systems:

- MES (Manufacturing Execution System): The brain. Manages production orders, material traceability (via barcode/RFID), quality data collection, equipment status monitoring.

- ERP: Upper-level resource planning.

- WMS (Warehouse Management System): Manages raw material and finished goods warehousing.

- Andon System: Enables real-time response to line abnormalities.

Phase 4: Construction, Implementation, and Operational Readiness

- Factory Construction and Utilities: Build according to layout, install power, compressed air, chilled water, vacuum lines, environmental (exhaust, wastewater) systems.

- Equipment Installation and Commissioning: Suppliers install equipment, followed by individual and line-wide debugging and testing.

- Team Building and Training: Recruit production, quality, maintenance, logistics management, and line operators. Conduct comprehensive safety, operational, and maintenance training.

- Supply Chain Establishment: Qualify suppliers, establish material procurement and delivery processes, validate with pilot production runs.

- Pilot Production and Ramp-up: Conduct multiple pilot runs to resolve process, equipment, and logistics issues, gradually increasing output to designed capacity.

Summary and Recommendations

For new entrants, a phased strategy is highly recommended:

- Start with a Final Assembly Plant First: Purchase major components like cabinets, doors, and liners externally. Focus on the three core processes: foaming, final assembly, and testing. This significantly reduces initial investment and complexity.

- Partner with Experienced Equipment Integrators or Industry Consultants: They can provide turnkey solutions or expert guidance to avoid pitfalls.

- Begin with Low-Volume Pilot Production: Validate the entire process and supply chain before scaling up.

Establishing a refrigerator factory is a capital and technology-intensive investment requiring meticulous planning and a deep understanding of manufacturing details. This guide aims to provide a clear roadmap for your endeavor.

Characteristics of a Refrigerator Assembly Line

How to Choose a Suitable Refrigerator Assembly Line?

Looking for air compressors? Contact us for more information.

Need assembly tools or other auxiliary equipment? Contact us for more information.