E-scooter Assembly Line—Characteristics of Two-Wheel Electric Vehicle Assembly Lines—What is an E-scooter Assembly Line?

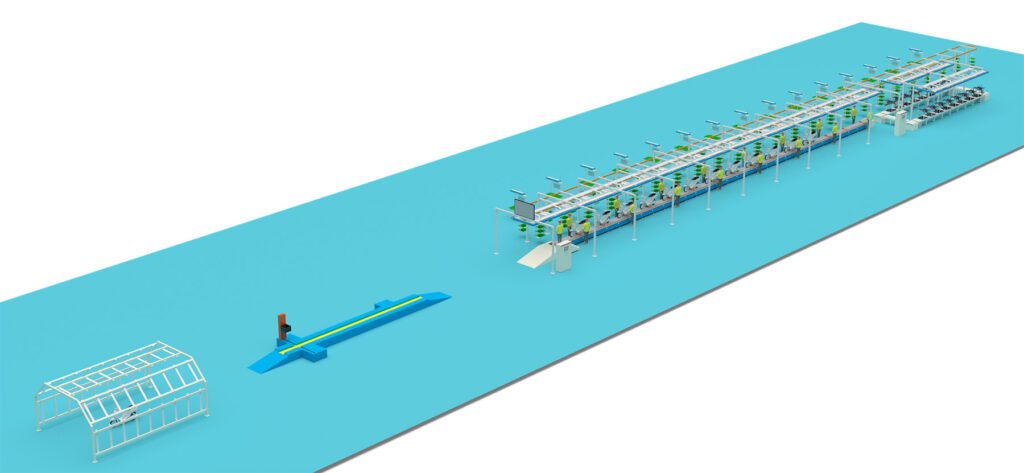

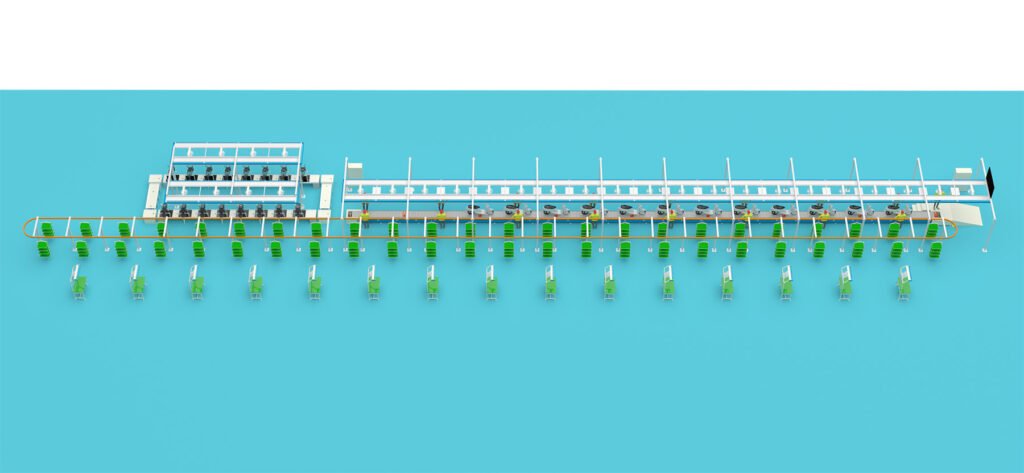

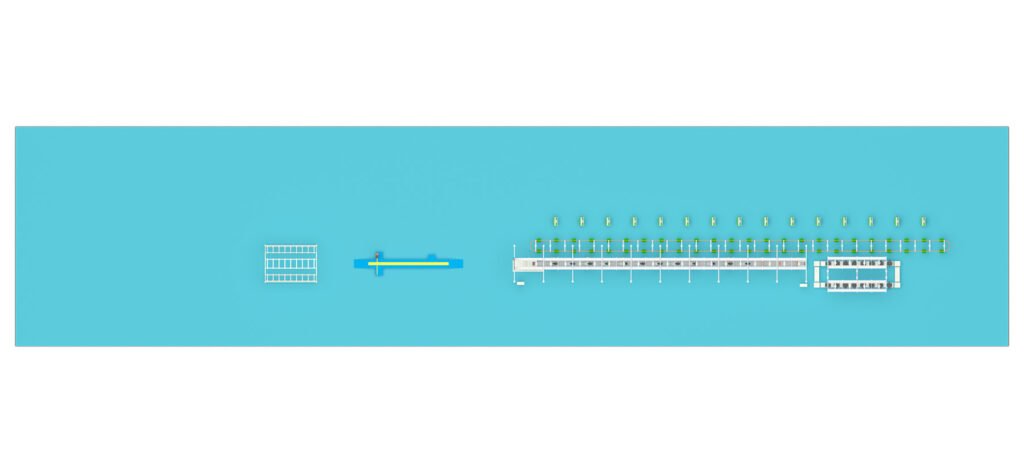

E-scooter Assembly Lines are suitable to Assemble/Produce E-scooters, 2 wheel Scooters, 2 wheel Electric-cycles, 2 wheel E-Bikes, 2 wheel Motorcycles, Bicycles, Bikes, and so on. (Sometimes, suitable for the production of Tricycles.)

Characteristics of Two-Wheel Electric Vehicle Assembly Lines

I. Core Characteristics: Differences from Traditional Motorcycle/Bicycle Assembly Lines

- Simplification and Increased Complexity of the Powertrain System:

- Simplification: Eliminates numerous mechanical components such as the internal combustion engine, fuel injection system, exhaust system, and complex transmission, reducing assembly steps.

- Increased Complexity: Introduces the “Three Core Electric Systems” – the motor, battery, and electronic controller – which form the heart and a new challenge of the assembly line.

- Transformation in Assembly Processes:

- Shift from Mechanical to Electrical Connections: Beyond bolts and welding, numerous wire harness connections and signal testing procedures are added. The wiring harness is more complex, integrating power, lighting, instrumentation, and intelligent controls.

- Quiet Assembly: The absence of engine noise creates a relatively quiet workshop environment, but demands higher Electrostatic Discharge (ESD) protection, especially in areas assembling electronic control units.

II. Main Stages and Features of the Assembly Line

A typical e-bike assembly line is usually divided into the following stages, each with distinct features:

- Frame Pre-treatment and Front Assembly Stage:

- Feature: Similar to bicycles. The frame is suspended, and the front fork, handlebars, instrument panel, etc., are installed. Main wire harness routing begins.

- Powertrain Installation Stage (Core Stage):

- Motor-Wheel Hub Assembly Installation: The rear wheel is often an integrated hub motor assembly, directly mounted to the swingarm, connecting the motor phase wires (thick) and Hall sensor wires (thin).

- Battery Compartment Preparation: The battery compartment dimensions, locks, and connectors are checked to ensure smooth battery insertion and reliable connection.

- Controller Installation: The motor controller (often an aluminum box) is fixed in a ventilated location, and connections to various wire harnesses begin.

- Electrical System Integration and Testing Stage (Critical Stage):

- Feature: This is the technical core of e-bike assembly.

- Full Vehicle Harness Interconnection: All electrical units are connected: controller, instrument panel, throttle grip, brake cut-off signal, lights, horn, etc.

- Initial Power-on Test: Before battery installation, an external power source may be used to check basic circuit continuity and light functionality.

- Insulation and Withstand Voltage Test: Safety tests are conducted on high-voltage parts (e.g., motor circuits) to prevent leakage.

- Battery Installation and Final Assembly Stage:

- Battery Loading: The charged battery pack (lead-acid or lithium) is placed into the vehicle body, secured, and the main power connector is plugged in. This is the key step that “gives life” to the vehicle.

- Dynamic Function Test: The throttle is engaged to test motor operation, brake cut-off function is verified, and various modes (speed levels, cruise control, parking mode, etc.) are checked.

- Exterior Parts Installation: Body plastic panels, fenders, seat, rearview mirrors, etc., are installed.

- Final Inspection and Adjustment Stage (Quality Gate):

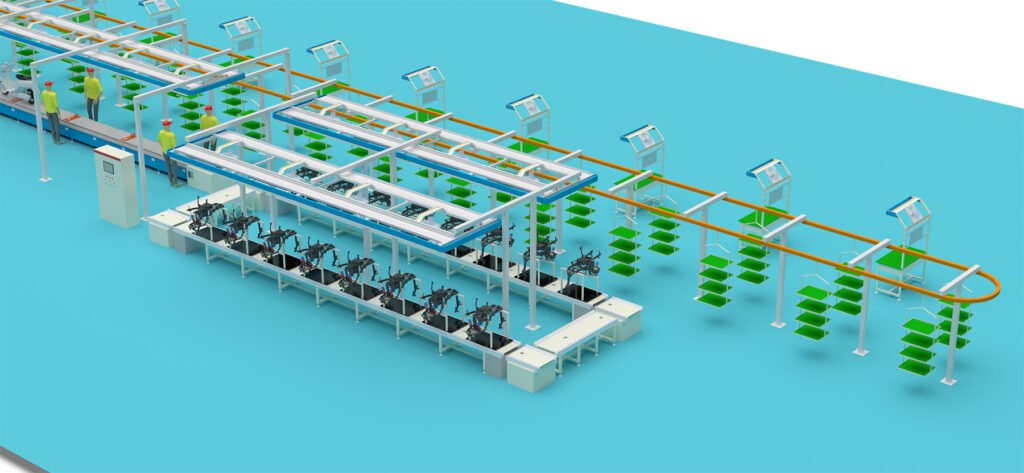

- “Road Test” Simulation: Operation is simulated on a roller dynamometer to test vehicle behavior, unusual noises, and braking performance at different speeds.

- Complete Vehicle Performance Check: Light beam pattern, braking distance, tire pressure, etc., are inspected.

- Smart System Activation: For smart e-bikes, Bluetooth/Wi-Fi/GPS module activation and binding tests are performed.

- Water Spray Test (Sampling): Checks the vehicle’s waterproof performance.

III. Prominent Trends in Modern/High-End Assembly Lines

- Flexibility and Modularity:

- A single line can handle mixed production of different models (e.g., simple scooters, light electric mopeds, electric motorcycles) through quick changeovers using AGVs or adjustable fixtures.

- The “Three Electric Systems” adopt a modular design to improve assembly efficiency and serviceability.

- Intelligentization and Data Traceability:

- Critical stations are equipped with torque tools and data collection systems to ensure fastener torque meets specifications and uploads data to servers, enabling full-process quality traceability.

- Scanning the vehicle’s VIN or RFID tag can retrieve all assembly data and component information for that specific unit.

- End-of-Line Diagnostic Systems: Quickly read data from the vehicle’s main controller via a dedicated interface to identify faults.

- Automation Applications:

- Robotic arms are introduced for tasks like handling heavy components (e.g., batteries), applying adhesive (e.g., for windshields), and wheel tightening.

- Automated conveyance systems (friction lines, pallet lines) are widely used.

- Changed Skill Requirements for Workers:

- Shift from traditional mechanical assemblers to multi-skilled technicians who need basic electrical circuit knowledge and the ability to use digital diagnostic equipment.

IV. Unique Challenges

- Battery Safety Handling: Particularly for lithium batteries, requiring extremely high standards for storage, handling, and assembly environment (fire and explosion prevention).

- Electromagnetic Compatibility (EMC) Issues: Motors and controllers generate electromagnetic interference during operation, which can affect instruments and smart systems. Assembly processes must ensure standardized wire harness routing and shielding.

- Software-Hardware Integration: Smart e-bikes require firmware flashing and parameter matching. The assembly line must possess “flashing” and software verification capabilities.

Summary

The core characteristic of a two-wheel electric vehicle assembly line is its electrified, integrated assembly process centered around the “Three Core Electric Systems.” It is more complex than bicycle assembly, cleaner and quieter than internal combustion motorcycle assembly, but adds numerous electrical connection and functional testing steps. Its development trend is moving towards greater flexibility, intelligence, traceability, and a stronger focus on electrical safety, evolving into a model of modern manufacturing that integrates mechanics, electronics, and software.

How to set up an E-scooter Assembly Line factory?

Looking for VIN marking machines? Contact us for more information.

Looking for air compressors? Contact us for more information.

Need assembly tools or auxiliary equipment? Contact us for more information.

Looking for E-scooter components? Contact us for more information.