Automobile Assembly Line—Key steps in delivering the Automotive Assembly Line solution to clients—How to set an Automotive Assembly Line?

Automobile Assembly Lines are suitable to Produce 4 wheelers, Cars, Sedans, SUVs, Automobiles, EVs, Mini Vans, Hybrid Models and so on. (Sometimes, suitable for the production of pickups.)

Steps to Provide an Automotive Assembly Line for a Customer

Phase 1: In-Depth Requirements Analysis & Strategic Planning

This is the foundation of the project, determining the technical direction and investment scale of the entire line.

- Product Engineering Analysis:

- Platform & Models: Determine whether it’s for a single model or mixed-model production (flexibility). Understand the platform architecture, body materials (steel, aluminum, composites).

- Product Data: Obtain complete vehicle BOM, 3D models, 2D drawings, especially critical assembly dimensions for the chassis, powertrain, and interior/exterior trim.

- Lifecycle: Understand the vehicle model’s lifecycle and whether the production line needs to allow for future upgrades or new models.

- Manufacturing Strategy & Capacity Planning:

- Production Takt Time: This is the absolute core. Calculate the second-level takt time based on annual production volume and operating schedule.

- Operating Schedule: Determine the number of shifts, working days per year, and required equipment uptime.

- Process Planning: Collaboratively define the boundaries of the four main shops (Stamping, Body Shop, Paint Shop, General Assembly). The focus is typically on the Assembly area.

- Capacity & Lean Production:

- Line Balancing: Analyze the operation time at each station, optimize task allocation, eliminate bottlenecks, and bring each station’s time as close as possible to the takt time.

- Logistics Plan: Plan the material delivery mode from suppliers to the line-side (sequencing, kanban, call systems, AGV/AGC, etc.).

- Automation & Intelligence Level:

- Define which stations must be automated and which are suitable for manual work.

- Define requirements for Smart Manufacturing and Data Traceability: Is an MES system needed? Are critical torques 100% recorded and traceable? Is an ANDON system required?

- Site & Infrastructure:

- Conduct a detailed survey of the plant conditions: area, ceiling height, floor load-bearing capacity, and utilities (power capacity, compressed air, network).

Phase 2: Detailed Solution Design & Engineering Development

(Select configurations based on your needs—some equipment are optional. Feel free to contact us for further details)

Transform the strategy into executable, detailed technical blueprints.

- Process Solution Design:

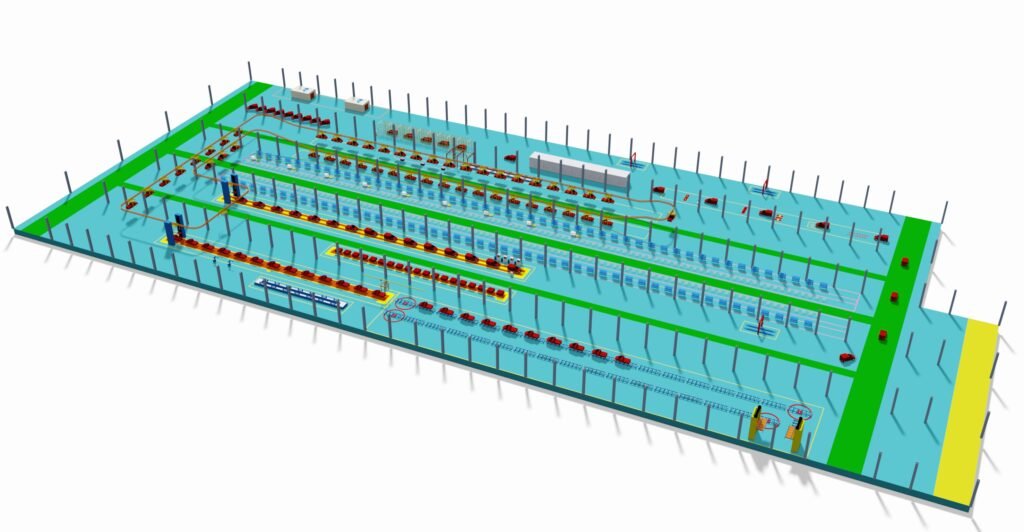

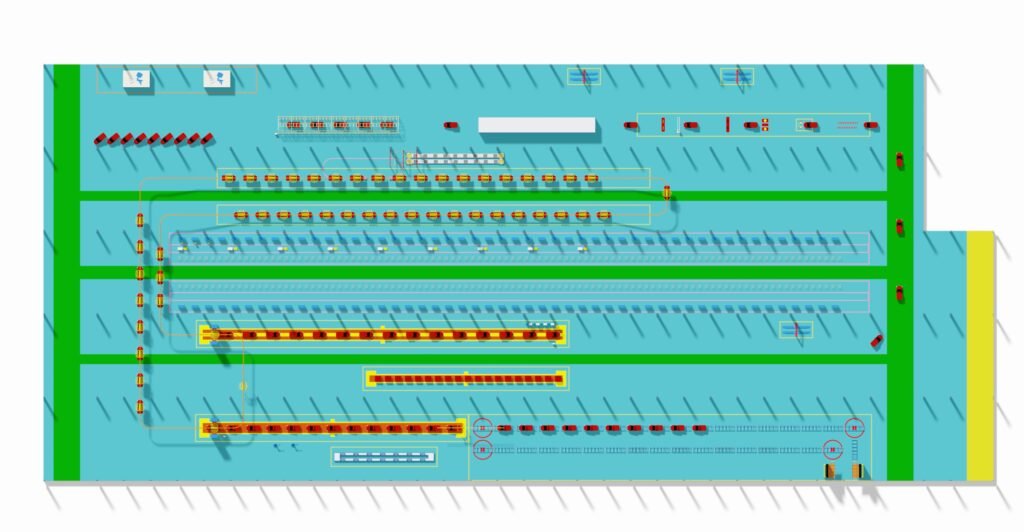

- Line Layout: Use CAD/3D software for detailed plant layout design, planning the material flow and spatial relationships between the main lines (Interior, Chassis, Final), sub-assembly lines (Doors, Cockpit, Engine Front Axle), and test lines (Wheel Alignment, Headlight Test, Roller Test).

- Process Sheets: Develop detailed work instructions for each station, including operation content, tools, materials, and quality requirements.

- Automation Solution Design:

- Mechanized Equipment: Design the conveying system, determining the drive and control systems.

- Robotic Applications: Plan robotic workstations, perform simulation to ensure reachability, cycle time, and safety.

- Special Purpose Equipment: Design non-standard automated equipment.

- Control System & IT Design:

- Electrical Control: Design the PLC network architecture, electrical schematics, and control panel layouts.

- Data Collection & Traceability: Design systems using RFID, barcodes, etc., for automatic vehicle identification and data collection at key stations, integrated with the MES.

- ANDON System: Design systems for material, quality, and equipment calls to enable transparent production management.

- HMI Design: Design user-friendly interfaces for operators and maintenance personnel.

- Logistics & Auxiliary Facility Design:

- Design line-side supermarkets, racks, and containers.

- Plan the placement and management of tools.

Phase 3: Procurement, Manufacturing

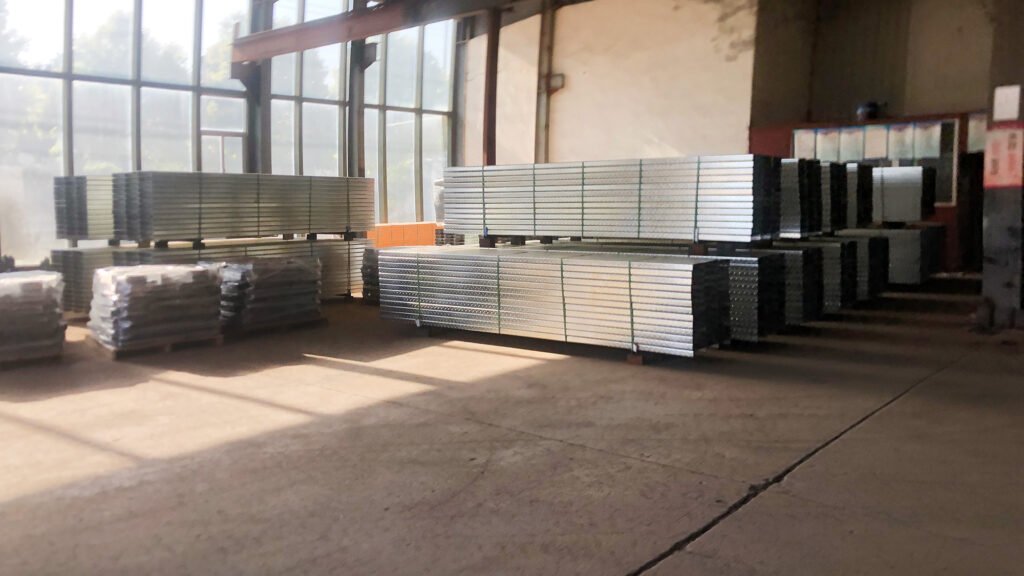

Transform the design blueprints into physical equipment.

- Supply Chain Management:

- High-quality components and custom fabricated parts.

- Strictly manage supplier delivery schedules and quality.

- Production:

- Perform machining, structural welding in-house or at partner facilities.

Phase 4: On-Site Installation, Commissioning

Assemble the “parts” into a “living” production line at the customer’s plant.

- Site Preparation & Equipment Move-In:

- Ensure the customer’s civil works and infrastructure are ready.

- Unpack, move, and position equipment.

- Mechanical/Electrical Installation:

- Install frames, conveyors, robots, platforms, etc.

- Complete all cable laying and pneumatic piping connections.

- On-Site Commissioning & Integration:

- Individual Equipment Commissioning: Power up and test basic functions of each device.

- Line Integration Commissioning: Integrate the entire conveying system for no-load operation.

- Commissioning with Vehicles/Carriers:

- Slow-Speed Debugging: Run with vehicle bodies or process carts at speeds lower than the takt time to verify all equipment works together.

- Takt Time Debugging: Gradually increase speed until the design takt time is reached, continuously optimizing.

- MES/Traceability System Integration Debugging: Verify the correctness and integrity of the vehicle data flow.

- Trial Run:

- SOP: Support the customer through low-volume trial production, producing the first saleable vehicles using real parts.

- Production Ramp-Up: Assist the customer in gradually increasing production speed from low rate to full capacity at the design takt time.

Phase 5: Training & Long-Term Support

Ensure the customer can operate the production line independently and efficiently.

- Comprehensive Training:

- Provide tiered training for operators, maintenance engineers, and production supervisors.

- Training content covers safe operation, daily checks, troubleshooting, and program backup.

- Documentation Handover:

- Deliver a project documentation, including: operation manuals, maintenance manuals, spare parts lists, etc.

- After-Sales & Continuous Support:

- Provide quick-response service during the warranty period.

- Supply spare parts and offer remote technical support.

Characteristics of an Automotive Assembly Line

Looking for VIN marking machines? Contact us for more information.

Need Filling Machines? Get expert support—request a quote or let’s talk about your project.

Looking for air compressors? Contact us for more information.

Need assembly tools or other auxiliary equipment? Contact us for more information.