ATV(All-Terrain Vehicle) Assembly Line—Characteristics of ATV(All-Terrain Vehicle) Assembly Lines—What is an All-Terrain Vehicle Assembly Line?

All-Terrain Vehicle (ATV/UTV) Assembly Line

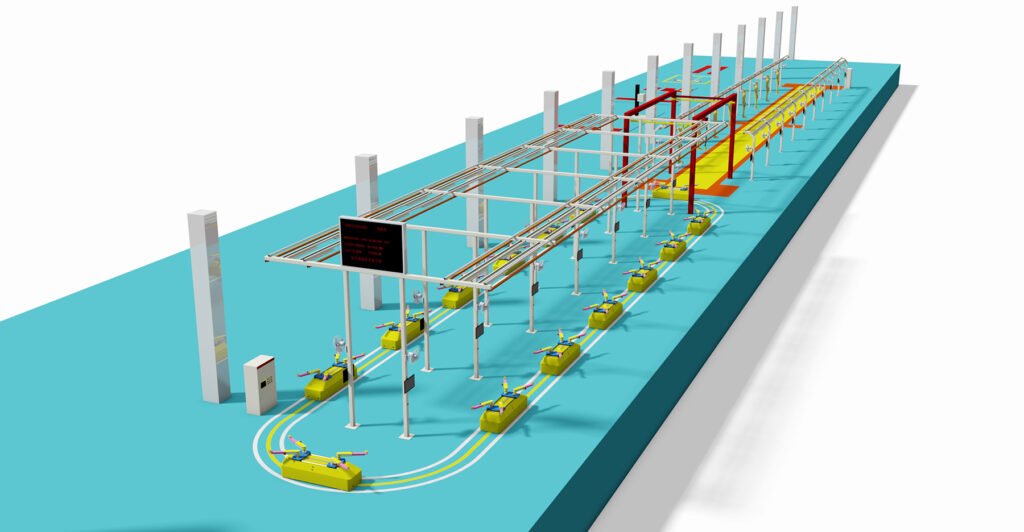

The assembly line for ATVs and UTVs is a specialized segment within automotive manufacturing, characterized by a blend of standardization and flexibility.

1. Key Characteristics of an ATV/UTV Assembly Line

Compared to large-scale automobile assembly lines, ATV/UTV lines typically exhibit the following:

- Strong Mixed-Model Capability: A single line may simultaneously assemble different models, colors, and configurations of ATVs and UTVs, placing high demands on material delivery and operator skills.

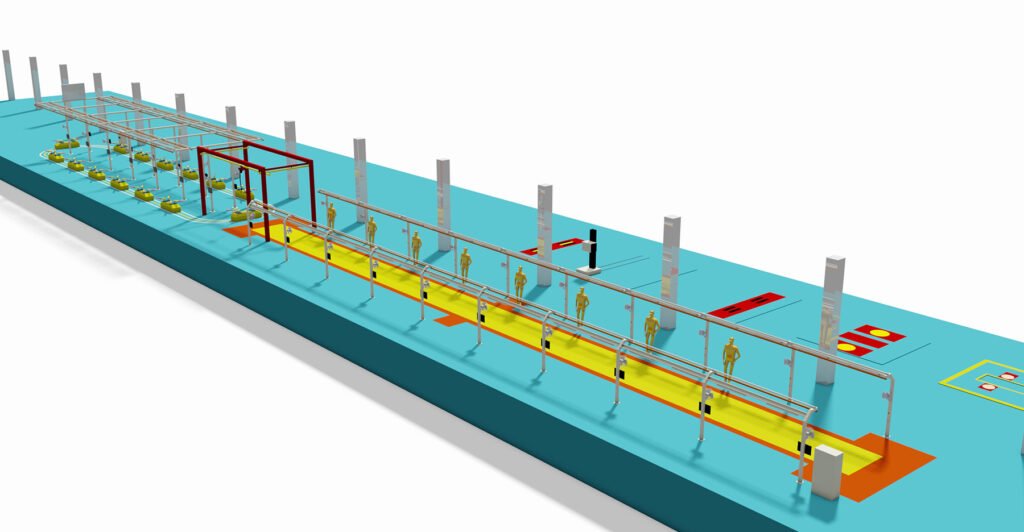

- Combination of Automation and Manual Labor: Critical stations (e.g., engine installation, wheel nut tightening, fluid filling, testing) utilize automated equipment, while many tasks like wiring harness routing and interior trim installation rely on skilled workers.

- Modular Assembly: Heavily employs sub-assembly modules, such as pre-assembled engine-transmission units, front/rear axle assemblies, and instrument panel modules, which are directly married to the main frame on the line.

2. Typical Assembly Line Process Flow (Main Line)

A complete ATV/UTV assembly line generally consists of the following main stages:

Phase 1: Interior and Wiring Harness Assembly

- Station 1: Frame Loading: The bare frame enters the station via a hoist or conveyor.

- Stations 2-5: Wiring Harness Routing and Securing: Installation of the full vehicle electrical harness, ECU, fuse box, etc.

- Stations 6-8: Fuel Tank, Lines, and Brake System: Installation of the fuel tank, brake lines, clutch cables, etc.

- Stations 9-10: Instrument Panel, Handlebars, and Control Assemblies: Installation of the gauge cluster, switches, handlebars, throttle/brake levers, etc.

Phase 2: Powertrain and Running Gear Marriage

- Station 11: Engine-Transmission Assembly Marriage: A core station, typically using a balancer or robotic arm to hoist and secure the powertrain to the frame.

- Station 12: Exhaust System Installation: Installation of the muffler and exhaust pipe.

- Station 13: Front/Rear Axle and Suspension Installation: Installation of axles, shock absorbers, and steering linkages.

- Station 14: Drive Shaft/Chain Installation: Connecting the transmission to the axles via drive shafts or the drive chain.

Phase 3: Exterior and Accessory Installation

- Station 15: Wheel Installation: Wheels are mounted and torqued to specification using automatic nut runners.

- Station 16: Body Panel Installation: Installation of front fenders, side panels, plastic body parts, etc.

- Station 17: Lights and Seat Installation: Installation of headlights, taillights, and the seat(s).

- Station 18: Windshield, Roof, and Cargo Bed (specific to UTVs).

Phase 4: Fluid Filling and Initial Testing

- Station 19: Fluid Filling: Automated equipment fills engine oil, gear oil, coolant, and brake fluid.

- Station 20: Preliminary Inspection: Connecting a diagnostic tool to read fault codes and check basic functions.

- Station 21: Line-Off Startup: Installing the battery and starting the engine for the first time.

Phase 5: Final Adjustment and Testing

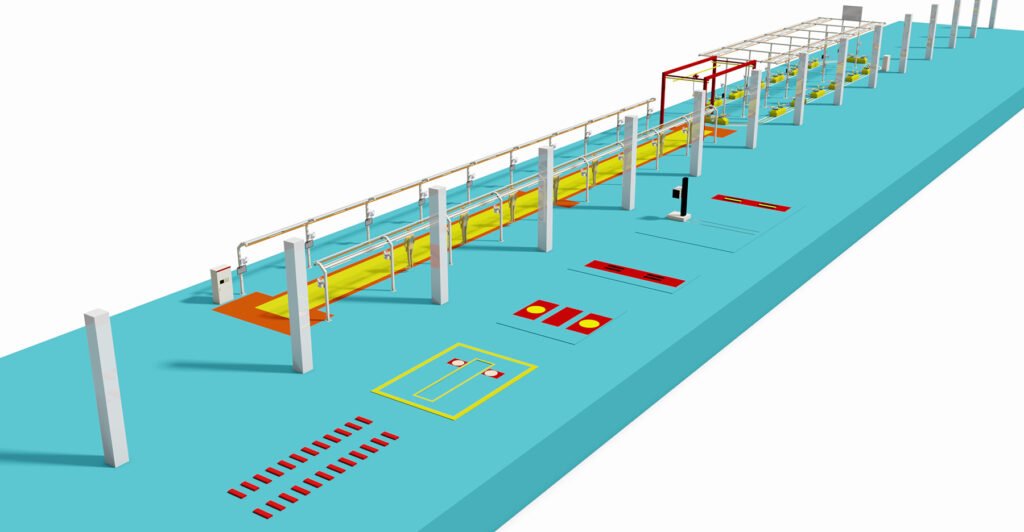

- PDA (Pre-Delivery Audit) Inspection Area: Functional tests for lights, brakes, steering, 4WD operation, differential lock, etc.

- Water Spray Test: Testing the vehicle’s waterproofing and sealing.

- Road Test Area (or Roller Dynamometer): A short actual driving test or simulated test to check for abnormal noises, vibration, shifting smoothness, etc.

- Final Adjustment and Cleaning: Correcting minor issues found during testing and performing a final exterior clean.

- Gate Release and Packaging: After final inspection approval, the vehicle is packaged (crated or simply protected) according to its destination market.

3. Key Equipment and Technologies

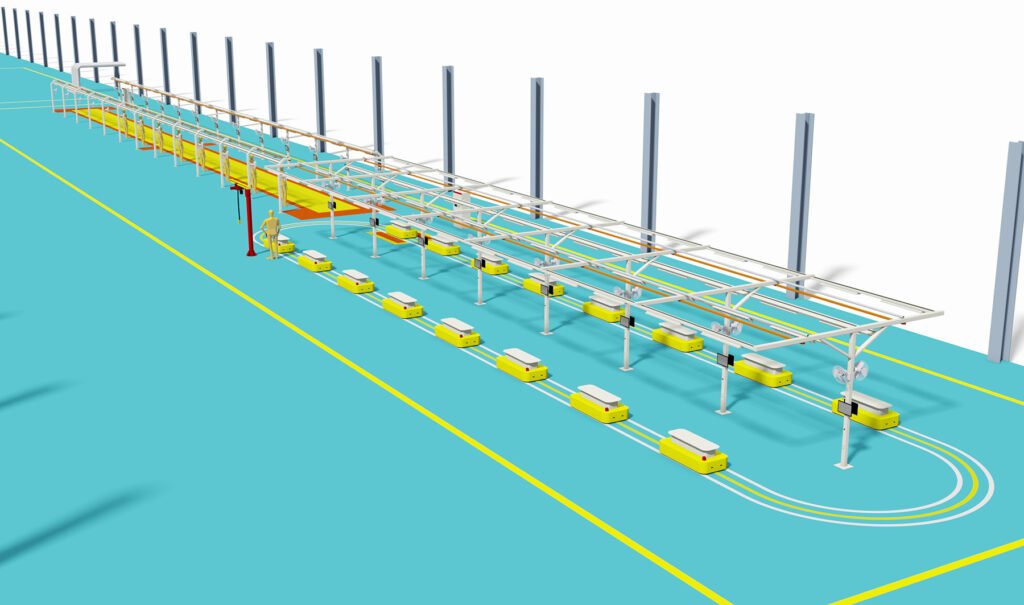

- Conveyance Systems: Drag chains, slat conveyors, overhead conveyors, RGVs (Rail Guided Vehicles), etc.

- Fastening Tools and Systems: Electric/pneumatic torque-controlled wrenches. Data for critical fasteners (e.g., wheels, engine mounts) is often recorded to a network for traceability.

- Automation Equipment: Balancers/robotic arms for engine/axle marriage, automatic fill machines, automatic wheel nut runners, automated windshield sealant applicators, etc.

- Testing and Diagnostic Equipment: End-of-Line electrical test systems, headlight aim testers, brake testers, side-slip testers, smoke leak detectors, chassis dynamometers, etc.

- Material Delivery Systems: SPS (Set Parts Supply) carts, Kanban systems, AGV delivery to ensure parts arrive at the workstation just-in-time and accurately.

4. Planning and Design Considerations

- Capacity Planning: Determining annual production volume and line takt time based on market demand.

- Flexibility Design: The line needs to accommodate future new models for mixed-model production.

- Ergonomics: Workstation design minimizes worker fatigue through the use of lift tables, rotating fixtures, balancers, etc.

- Quality Traceability: Using VIN or RFID tags to bind and trace data from key components through the entire vehicle assembly process.

- Environmental and Safety: Essential provisions include waste fluid recovery, noise control, safety light curtains, emergency stop systems, etc.

5. Industry Trends

- Electrification Shift: Assembly lines for electric ATVs/UTVs differ significantly, involving new processes like battery pack installation, electric motor mounting, high-voltage wiring, and safety testing.

- Smart and Data-Driven Manufacturing: Widespread adoption of MES (Manufacturing Execution Systems), IoT, and digital twin technologies for real-time production monitoring, quality prediction, and efficiency optimization.

- Personalization/Customization: To accommodate growing customer demand for personalization (e.g., colors, accessories), assembly lines require more intelligent order management and material pull systems.

Summary

An ATV/UTV assembly line is a precisely organized manufacturing system that efficiently and with high quality integrates hundreds of components into a vehicle designed for fun and utility. While it follows general principles of automotive manufacturing, it exhibits unique characteristics due to its product nature and market scale. Evolving with technology and market changes, this type of assembly line is continuously moving towards greater flexibility, intelligence, and sustainability.

If you are considering building a new assembly line or undertaking a technical upgrade, more specific planning is required based on product process analysis, production capacity targets, investment budget, and other factors.

How to set up a ATV(All-Terrain Vehicle) Assembly Line factory?

Find the Testing Line or Equipment for Your Needs. Get expert support—request a quote or let’s talk about your project.

Need Coating Line or Coating Equipment? Get expert support—request a quote or let’s talk about your project.

Looking for VIN marking machines? Contact us for more information.

Need Filling Machines? Get expert support—request a quote or let’s talk about your project.

Looking for air compressors? Contact us for more information.

Need assembly tools? Contact us for more information.