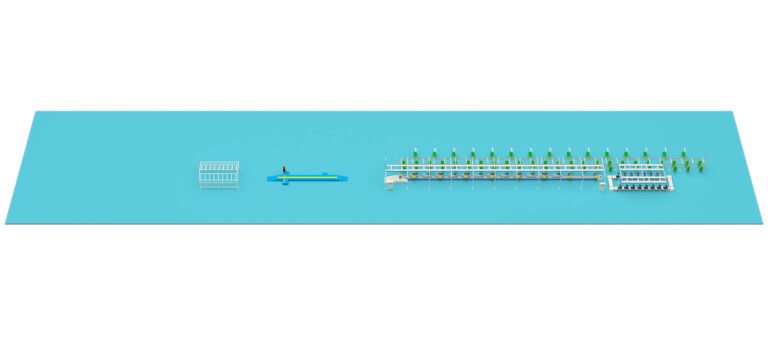

Top-Loading Washing Machine Assembly Line—Key Characteristics of a Tumble Washer (Top-Loading Washer) Assembly Line

Washing Machine Assembly Lines/Production Lines are Suitable to Assemble/Produce Washing machines.(Welcome to contact us, we will suggest and design the suitable Assembly Lines/Production Lines for you.)

Key Characteristics of a Tumble Washer (Top-Loading Washer) Assembly Line

The main characteristics of a tumble washer assembly line are reflected in its high efficiency, modular design, emphasis on balance and vibration dampening, and stringent functional testing requirements. Below is a detailed breakdown of the core features:

1. High Standardization and Takt-Based Production

- Assembly Line Operation: Strictly follows a predefined assembly sequence. Each workstation completes specific tasks within a fixed “takt time,” ensuring a stable production rhythm and maximizing efficiency.

- Workstation Specialization: Operators focus on a limited number of steps, leading to high proficiency, reduced errors, and improved overall speed and quality consistency.

2. Modular Assembly Centered Around the “Tub Module”

This is a prominent feature of tumble washer assembly.

- Sub-Line Pre-Assembly: The core tub module (inner tub, balance ring, outer tub, clutch/motor, suspension rods, etc.) is independently assembled and preliminarily adjusted on a sub-line adjacent to the main line.

- Modular Integration: The pre-assembled “tub module” is handled as a single unit and hoisted into the cabinet in one motion at a main line station. This significantly simplifies the main line processes, enhancing its efficiency and flexibility.

3. Clearly Defined Critical Quality Control Points

The assembly line incorporates strict quality “gates”:

- Suspension Rod Installation & Balancing: The installation quality and length adjustment of the suspension rods (or dampers) directly determine the spin stability and noise level of the washer, making it one of the most critical control points.

- Drive System Alignment: Ensuring the concentric alignment of the motor shaft, clutch, and inner tub axis to prevent abnormal vibration and noise.

- Air-Tightness & Leak Testing: Conducting rigorous pressure tests on the water inlet lines, outer tub, and drainage system to ensure no leaks.

- Comprehensive Functional Testing: All finished products must undergo a fully automatic test run, simulating the entire wash and spin cycle to check program logic, spin speed, abnormal vibration, electrical safety, etc.

4. Ergonomic and Flexible Design

- Material Handling Assist Devices: Widespread use of balancers, power-assisted arms, etc., to help workers handle heavy tub modules and concrete counterweights, reducing physical strain.

- Flexible Production Line: Through quick changeovers and fixture adjustments, a single assembly line can be configured to produce tumble washers of different capacities (e.g., 6kg, 8kg, 10kg) and models, adapting to changing market demands.

5. High Automation in Key Processes

Although many manual steps remain in tumble washer assembly, key stations have achieved automation:

- Automatic Fastening: Screws in critical locations (e.g., suspension rod nuts, motor mounting screws) are tightened by automatic screwdrivers, ensuring precise and consistent torque.

- Automatic Testing: Safety performance tests (dielectric strength, ground continuity) and functional tests are mostly performed and data-logged automatically by equipment.

- Automatic Labeling: Energy labels, rating plates, etc., are applied by automatic labeling machines, ensuring precise placement and improving efficiency.

6. Vibration Dampening and Balance Processes Throughout

Due to its wash/spin principle, tumble washers have high vibration control requirements, which are addressed through these assembly line processes:

- Precise adjustment of suspension rods (or dampers).

- Accurate installation of counterweights: Installing top and bottom counterweights is a core step for suppressing vibration and ensuring dynamic balance.

- Secure fastening of the cabinet and base: Ensures overall structural rigidity to avoid resonance.

7. Digitalization and Traceability

- MES Integration: Scanning barcodes of key components (e.g., motor, control board) enables full-process quality traceability. Any issue can be traced back to the specific workstation, component batch, and operator.

- Andon System: Any workstation can immediately signal a stop and call for help if an abnormality occurs, enabling rapid response and preventing defects from moving to the next station.